Page 296 - Biofuels Refining and Performance

P. 296

Fuel Cells 275

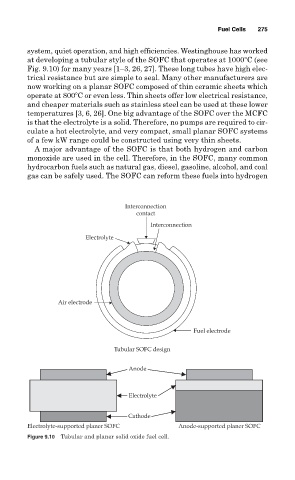

system, quiet operation, and high efficiencies. Westinghouse has worked

at developing a tubular style of the SOFC that operates at 1000 C (see

Fig. 9.10) for many years [1–3, 26, 27]. These long tubes have high elec-

trical resistance but are simple to seal. Many other manufacturers are

now working on a planar SOFC composed of thin ceramic sheets which

operate at 800 C or even less. Thin sheets offer low electrical resistance,

and cheaper materials such as stainless steel can be used at these lower

temperatures [3, 6, 26]. One big advantage of the SOFC over the MCFC

is that the electrolyte is a solid. Therefore, no pumps are required to cir-

culate a hot electrolyte, and very compact, small planar SOFC systems

of a few kW range could be constructed using very thin sheets.

A major advantage of the SOFC is that both hydrogen and carbon

monoxide are used in the cell. Therefore, in the SOFC, many common

hydrocarbon fuels such as natural gas, diesel, gasoline, alcohol, and coal

gas can be safely used. The SOFC can reform these fuels into hydrogen

Interconnection

contact

Interconnection

Electrolyte

Air electrode

Fuel electrode

Tubular SOFC design

Anode

Electrolyte

Cathode

Electrolyte-supported planer SOFC Anode-supported planer SOFC

Figure 9.10 Tubular and planer solid oxide fuel cell.