Page 153 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 153

130 Biomass Gasification, Pyrolysis and Torrefaction

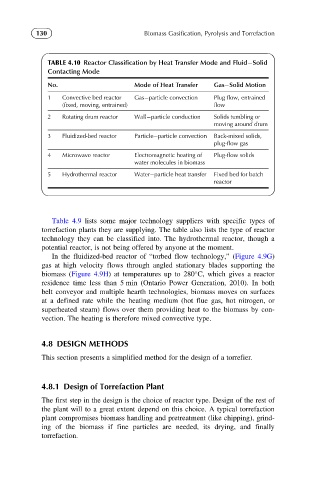

TABLE 4.10 Reactor Classification by Heat Transfer Mode and Fluid Solid

Contacting Mode

No. Mode of Heat Transfer Gas Solid Motion

1 Convective bed reactor Gas particle convection Plug flow, entrained

(fixed, moving, entrained) flow

2 Rotating drum reactor Wall particle conduction Solids tumbling or

moving around drum

3 Fluidized-bed reactor Particle particle convection Back-mixed solids,

plug-flow gas

4 Microwave reactor Electromagnetic heating of Plug-flow solids

water molecules in biomass

5 Hydrothermal reactor Water particle heat transfer Fixed bed for batch

reactor

Table 4.9 lists some major technology suppliers with specific types of

torrefaction plants they are supplying. The table also lists the type of reactor

technology they can be classified into. The hydrothermal reactor, though a

potential reactor, is not being offered by anyone at the moment.

In the fluidized-bed reactor of “torbed flow technology,” (Figure 4.9G)

gas at high velocity flows through angled stationary blades supporting the

biomass (Figure 4.9H) at temperatures up to 280 C, which gives a reactor

residence time less than 5 min (Ontario Power Generation, 2010). In both

belt conveyor and multiple hearth technologies, biomass moves on surfaces

at a defined rate while the heating medium (hot flue gas, hot nitrogen, or

superheated steam) flows over them providing heat to the biomass by con-

vection. The heating is therefore mixed convective type.

4.8 DESIGN METHODS

This section presents a simplified method for the design of a torrefier.

4.8.1 Design of Torrefaction Plant

The first step in the design is the choice of reactor type. Design of the rest of

the plant will to a great extent depend on this choice. A typical torrefaction

plant compromises biomass handling and pretreatment (like chipping), grind-

ing of the biomass if fine particles are needed, its drying, and finally

torrefaction.