Page 155 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 155

132 Biomass Gasification, Pyrolysis and Torrefaction

Cold air

Cooled

Torrefield torrefied

Raw Dry

biomass biomass

biomass biomass

Cooler

Dryer Torrefier

Flue gass Warm air

Oil burner

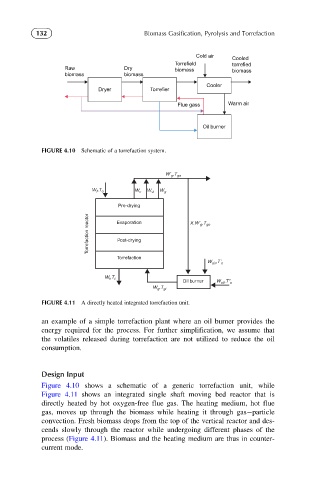

FIGURE 4.10 Schematic of a torrefaction system.

W’ g ,T go

W f ,T o W v W vl W g

Pre-drying

Torrefaction reactor Evaporation X.W’ g ,T go

Post-drying

Torrefaction

W air ,T’ o

W t ,T t

Oil burner W oil ,T” o

W g ,T gi

FIGURE 4.11 A directly heated integrated torrefaction unit.

an example of a simple torrefaction plant where an oil burner provides the

energy required for the process. For further simplification, we assume that

the volatiles released during torrefaction are not utilized to reduce the oil

consumption.

Design Input

Figure 4.10 shows a schematic of a generic torrefaction unit, while

Figure 4.11 shows an integrated single shaft moving bed reactor that is

directly heated by hot oxygen-free flue gas. The heating medium, hot flue

gas, moves up through the biomass while heating it through gas particle

convection. Fresh biomass drops from the top of the vertical reactor and des-

cends slowly through the reactor while undergoing different phases of the

process (Figure 4.11). Biomass and the heating medium are thus in counter-

current mode.