Page 275 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 275

Chapter | 8 Design of Biomass Gasifiers 251

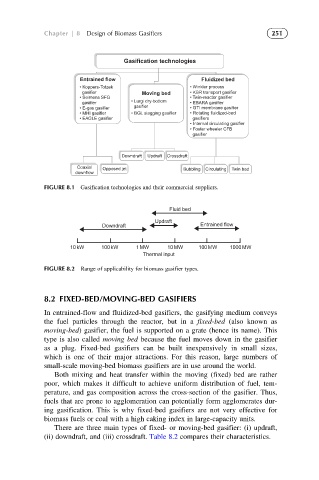

Gasification technologies

Entrained flow Fluidized bed

• Koppers-Totzek • Winkler process

gasifier Moving bed • KBR transport gasifier

• Seimens SFG • Twin-reactor gasifier

gasifier • Lurgi dry-bottom • EBARA gasifier

• E-gas gasifier gasifier • GTI membrane gasifier

• MHI gasifier • BGL slagging gasifier • Rotating fluidized-bed

• EAGLE gasifier gasifiers

• Internal circulating gasifier

• Foster wheeler CFB

gasifier

Downdraft Updraft Crossdraft

Coaxial Opposed jet Bubbling Circulating Twin bed

downflow

FIGURE 8.1 Gasification technologies and their commercial suppliers.

Fluid bed

Updraft

Downdraft Entrained flow

10kW 100kW 1MW 10MW 100MW 1000MW

Thermal input

FIGURE 8.2 Range of applicability for biomass gasifier types.

8.2 FIXED-BED/MOVING-BED GASIFIERS

In entrained-flow and fluidized-bed gasifiers, the gasifying medium conveys

the fuel particles through the reactor, but in a fixed-bed (also known as

moving-bed) gasifier, the fuel is supported on a grate (hence its name). This

type is also called moving bed because the fuel moves down in the gasifier

as a plug. Fixed-bed gasifiers can be built inexpensively in small sizes,

which is one of their major attractions. For this reason, large numbers of

small-scale moving-bed biomass gasifiers are in use around the world.

Both mixing and heat transfer within the moving (fixed) bed are rather

poor, which makes it difficult to achieve uniform distribution of fuel, tem-

perature, and gas composition across the cross-section of the gasifier. Thus,

fuels that are prone to agglomeration can potentially form agglomerates dur-

ing gasification. This is why fixed-bed gasifiers are not very effective for

biomass fuels or coal with a high caking index in large-capacity units.

There are three main types of fixed- or moving-bed gasifier: (i) updraft,

(ii) downdraft, and (iii) crossdraft. Table 8.2 compares their characteristics.