Page 277 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 277

Chapter | 8 Design of Biomass Gasifiers 253

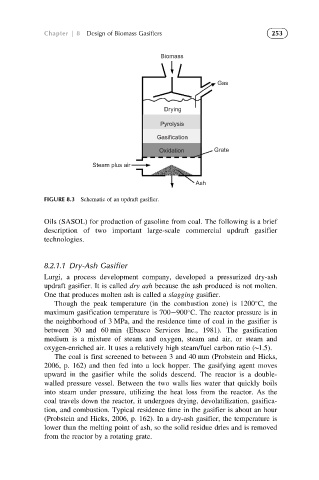

Biomass

Gas

Drying

Pyrolysis

Gasification

Oxidation Grate

Steam plus air

Ash

FIGURE 8.3 Schematic of an updraft gasifier.

Oils (SASOL) for production of gasoline from coal. The following is a brief

description of two important large-scale commercial updraft gasifier

technologies.

8.2.1.1 Dry-Ash Gasifier

Lurgi, a process development company, developed a pressurized dry-ash

updraft gasifier. It is called dry ash because the ash produced is not molten.

One that produces molten ash is called a slagging gasifier.

Though the peak temperature (in the combustion zone) is 1200 C, the

maximum gasification temperature is 700 900 C. The reactor pressure is in

the neighborhood of 3 MPa, and the residence time of coal in the gasifier is

between 30 and 60 min (Ebasco Services Inc., 1981). The gasification

medium is a mixture of steam and oxygen, steam and air, or steam and

oxygen-enriched air. It uses a relatively high steam/fuel carbon ratio (B1.5).

The coal is first screened to between 3 and 40 mm (Probstein and Hicks,

2006, p. 162) and then fed into a lock hopper. The gasifying agent moves

upward in the gasifier while the solids descend. The reactor is a double-

walled pressure vessel. Between the two walls lies water that quickly boils

into steam under pressure, utilizing the heat loss from the reactor. As the

coal travels down the reactor, it undergoes drying, devolatilization, gasifica-

tion, and combustion. Typical residence time in the gasifier is about an hour

(Probstein and Hicks, 2006, p. 162). In a dry-ash gasifier, the temperature is

lower than the melting point of ash, so the solid residue dries and is removed

from the reactor by a rotating grate.