Page 279 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 279

Chapter | 8 Design of Biomass Gasifiers 255

Biomass

Drying

Pyrolysis

Air Air

Combustion

Gasification

Gas

FIGURE 8.4 Schematic of a throated-type downdraft gasifier.

Biomass

I Biomass fuel

II Flaming pyrolysis

Air nozzles Air

III Char combustion

IV Char gasification

Product gas 500 1000 1500

Temperature (K)

Ash

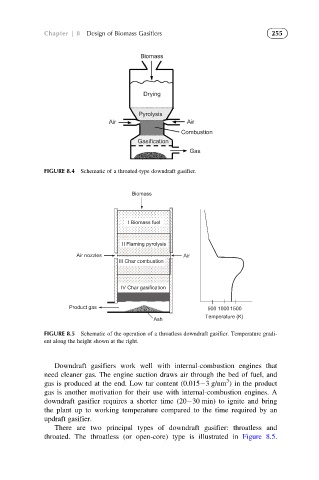

FIGURE 8.5 Schematic of the operation of a throatless downdraft gasifier. Temperature gradi-

ent along the height shown at the right.

Downdraft gasifiers work well with internal-combustion engines that

need cleaner gas. The engine suction draws air through the bed of fuel, and

3

gas is produced at the end. Low tar content (0.015 3 g/nm ) in the product

gas is another motivation for their use with internal-combustion engines. A

downdraft gasifier requires a shorter time (20 30 min) to ignite and bring

the plant up to working temperature compared to the time required by an

updraft gasifier.

There are two principal types of downdraft gasifier: throatless and

throated. The throatless (or open-core) type is illustrated in Figure 8.5.