Page 284 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 284

260 Biomass Gasification, Pyrolysis and Torrefaction

Gas outlet

Gas take-off

Dust separator

Coal

bunker

Return pipe for

accycling fuel

Gasifier

(5½-ft deep fluidized bed)

Screw feed

Traveling grate

Air or oxygen tuyere

Steam

Ash pit

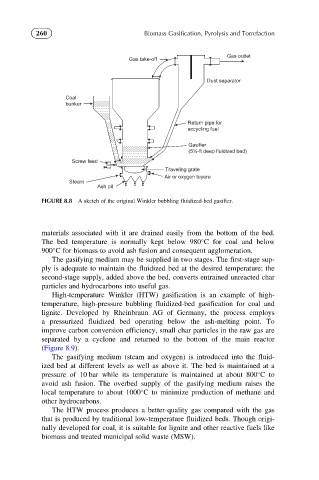

FIGURE 8.8 A sketch of the original Winkler bubbling fluidized-bed gasifier.

materials associated with it are drained easily from the bottom of the bed.

The bed temperature is normally kept below 980 C for coal and below

900 C for biomass to avoid ash fusion and consequent agglomeration.

The gasifying medium may be supplied in two stages. The first-stage sup-

ply is adequate to maintain the fluidized bed at the desired temperature; the

second-stage supply, added above the bed, converts entrained unreacted char

particles and hydrocarbons into useful gas.

High-temperature Winkler (HTW) gasification is an example of high-

temperature, high-pressure bubbling fluidized-bed gasification for coal and

lignite. Developed by Rheinbraun AG of Germany, the process employs

a pressurized fluidized bed operating below the ash-melting point. To

improve carbon conversion efficiency, small char particles in the raw gas are

separated by a cyclone and returned to the bottom of the main reactor

(Figure 8.9).

The gasifying medium (steam and oxygen) is introduced into the fluid-

ized bed at different levels as well as above it. The bed is maintained at a

pressure of 10 bar while its temperature is maintained at about 800 Cto

avoid ash fusion. The overbed supply of the gasifying medium raises the

local temperature to about 1000 C to minimize production of methane and

other hydrocarbons.

The HTW process produces a better-quality gas compared with the gas

that is produced by traditional low-temperature fluidized beds. Though origi-

nally developed for coal, it is suitable for lignite and other reactive fuels like

biomass and treated municipal solid waste (MSW).