Page 285 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 285

Chapter | 8 Design of Biomass Gasifiers 261

Syngas

cooler

HTW

Feed gasifier

Freeboard

Lock

hopper

Fluid bed

Feed

Air/oxygen/ screw

steam

Cooling screw

Lock

hopper

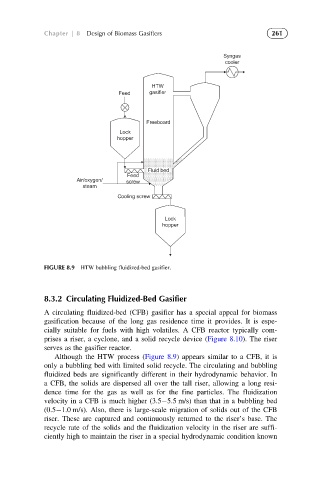

FIGURE 8.9 HTW bubbling fluidized-bed gasifier.

8.3.2 Circulating Fluidized-Bed Gasifier

A circulating fluidized-bed (CFB) gasifier has a special appeal for biomass

gasification because of the long gas residence time it provides. It is espe-

cially suitable for fuels with high volatiles. A CFB reactor typically com-

prises a riser, a cyclone, and a solid recycle device (Figure 8.10). The riser

serves as the gasifier reactor.

Although the HTW process (Figure 8.9) appears similar to a CFB, it is

only a bubbling bed with limited solid recycle. The circulating and bubbling

fluidized beds are significantly different in their hydrodynamic behavior. In

a CFB, the solids are dispersed all over the tall riser, allowing a long resi-

dence time for the gas as well as for the fine particles. The fluidization

velocity in a CFB is much higher (3.5 5.5 m/s) than that in a bubbling bed

(0.5 1.0 m/s). Also, there is large-scale migration of solids out of the CFB

riser. These are captured and continuously returned to the riser’s base. The

recycle rate of the solids and the fluidization velocity in the riser are suffi-

ciently high to maintain the riser in a special hydrodynamic condition known