Page 290 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 290

266 Biomass Gasification, Pyrolysis and Torrefaction

Upflowing Downflowing

chamber chamber

Fluidizing agents

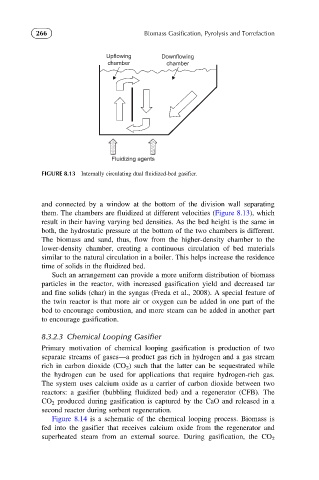

FIGURE 8.13 Internally circulating dual fluidized-bed gasifier.

and connected by a window at the bottom of the division wall separating

them. The chambers are fluidized at different velocities (Figure 8.13), which

result in their having varying bed densities. As the bed height is the same in

both, the hydrostatic pressure at the bottom of the two chambers is different.

The biomass and sand, thus, flow from the higher-density chamber to the

lower-density chamber, creating a continuous circulation of bed materials

similar to the natural circulation in a boiler. This helps increase the residence

time of solids in the fluidized bed.

Such an arrangement can provide a more uniform distribution of biomass

particles in the reactor, with increased gasification yield and decreased tar

and fine solids (char) in the syngas (Freda et al., 2008). A special feature of

the twin reactor is that more air or oxygen can be added in one part of the

bed to encourage combustion, and more steam can be added in another part

to encourage gasification.

8.3.2.3 Chemical Looping Gasifier

Primary motivation of chemical looping gasification is production of two

separate streams of gases—a product gas rich in hydrogen and a gas stream

rich in carbon dioxide (CO 2 ) such that the latter can be sequestrated while

the hydrogen can be used for applications that require hydrogen-rich gas.

The system uses calcium oxide as a carrier of carbon dioxide between two

reactors: a gasifier (bubbling fluidized bed) and a regenerator (CFB). The

CO 2 produced during gasification is captured by the CaO and released in a

second reactor during sorbent regeneration.

Figure 8.14 is a schematic of the chemical looping process. Biomass is

fed into the gasifier that receives calcium oxide from the regenerator and

superheated steam from an external source. During gasification, the CO 2