Page 294 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 294

270 Biomass Gasification, Pyrolysis and Torrefaction

Fuel Gas to pilot burner

Oxygen

Burner

Pressure

water outlet

Cooling screen

Pressure

water inlet

Quench

water

Cooling jacket

Gas outlet

Water

overflow

Granulated slag

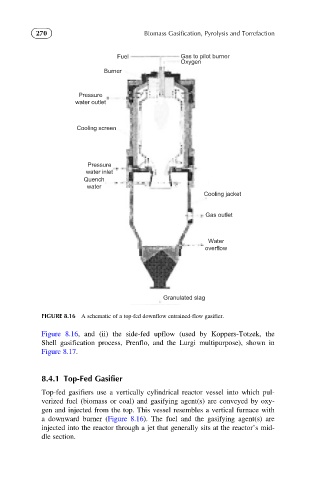

FIGURE 8.16 A schematic of a top-fed downflow entrained-flow gasifier.

Figure 8.16, and (ii) the side-fed upflow (used by Koppers-Totzek, the

Shell gasification process, Prenflo, and the Lurgi multipurpose), shown in

Figure 8.17.

8.4.1 Top-Fed Gasifier

Top-fed gasifiers use a vertically cylindrical reactor vessel into which pul-

verized fuel (biomass or coal) and gasifying agent(s) are conveyed by oxy-

gen and injected from the top. This vessel resembles a vertical furnace with

a downward burner (Figure 8.16). The fuel and the gasifying agent(s) are

injected into the reactor through a jet that generally sits at the reactor’s mid-

dle section.