Page 295 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 295

Chapter | 8 Design of Biomass Gasifiers 271

Syngas to

treating

Hot candle

filter

Fire tube

boiler

Second

stage

Coal

slurry

Char

recycle

First stage

Oxygen

Slag/water

Refractory

slurry

Slag

by-product

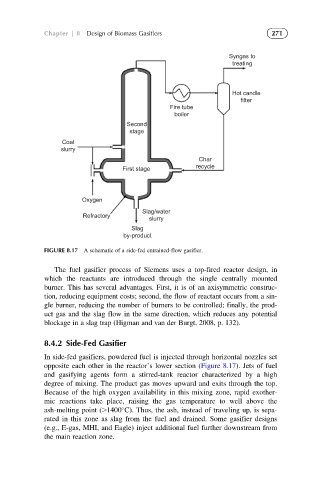

FIGURE 8.17 A schematic of a side-fed entrained-flow gasifier.

The fuel gasifier process of Siemens uses a top-fired reactor design, in

which the reactants are introduced through the single centrally mounted

burner. This has several advantages. First, it is of an axisymmetric construc-

tion, reducing equipment costs; second, the flow of reactant occurs from a sin-

gle burner, reducing the number of burners to be controlled; finally, the prod-

uct gas and the slag flow in the same direction, which reduces any potential

blockage in a slag trap (Higman and van der Burgt, 2008, p. 132).

8.4.2 Side-Fed Gasifier

In side-fed gasifiers, powdered fuel is injected through horizontal nozzles set

opposite each other in the reactor’s lower section (Figure 8.17). Jets of fuel

and gasifying agents form a stirred-tank reactor characterized by a high

degree of mixing. The product gas moves upward and exits through the top.

Because of the high oxygen availability in this mixing zone, rapid exother-

mic reactions take place, raising the gas temperature to well above the

ash-melting point (.1400 C). Thus, the ash, instead of traveling up, is sepa-

rated in this zone as slag from the fuel and drained. Some gasifier designs

(e.g., E-gas, MHI, and Eagle) inject additional fuel further downstream from

the main reaction zone.