Page 298 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 298

274 Biomass Gasification, Pyrolysis and Torrefaction

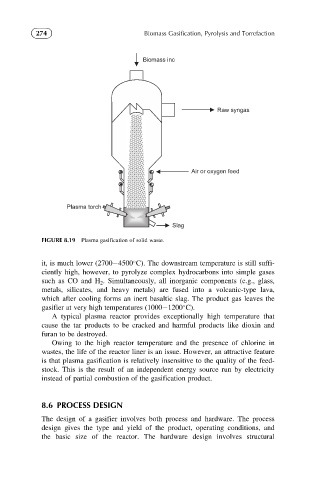

Biomass inc

Raw syngas

Air or oxygen feed

Plasma torch

Slag

FIGURE 8.19 Plasma gasification of solid waste.

it, is much lower (2700 4500 C). The downstream temperature is still suffi-

ciently high, however, to pyrolyze complex hydrocarbons into simple gases

such as CO and H 2 . Simultaneously, all inorganic components (e.g., glass,

metals, silicates, and heavy metals) are fused into a volcanic-type lava,

which after cooling forms an inert basaltic slag. The product gas leaves the

gasifier at very high temperatures (1000 1200 C).

A typical plasma reactor provides exceptionally high temperature that

cause the tar products to be cracked and harmful products like dioxin and

furan to be destroyed.

Owing to the high reactor temperature and the presence of chlorine in

wastes, the life of the reactor liner is an issue. However, an attractive feature

is that plasma gasification is relatively insensitive to the quality of the feed-

stock. This is the result of an independent energy source run by electricity

instead of partial combustion of the gasification product.

8.6 PROCESS DESIGN

The design of a gasifier involves both process and hardware. The process

design gives the type and yield of the product, operating conditions, and

the basic size of the reactor. The hardware design involves structural