Page 302 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 302

278 Biomass Gasification, Pyrolysis and Torrefaction

actual air

ERð,1:0Þ 5 5 EAð.1:0Þ (8.12)

gasification combustion

stoichiometric air

In a combustor, the amount of air supplied is determined by the stoichio-

metric (or theoretical) amount of air and its excess air coefficient.Ina

gasifier, the air supply is only a fraction of the stoichiometric amount. The

stoichiometric amount of air may be calculated based on the ultimate

analysis of the fuel.

ER dictates the performance of the gasifier. For example, pyrolysis takes

place in the absence of air and hence the ER is zero; for gasification of bio-

mass, it lies between 0.2 and 0.3.

Downdraft gasifiers give the best yield for ER—0.25 (Reed and Das,

1988, p. 25). With a lower ER value, the char is not fully converted into

gases. Some units deliberately operate with a low ER to maximize their char-

coal production. A lower ER gives rise to higher tar production. So, updraft

gasifiers, which typically operate with an ER of less than 0.25, have higher

tar content. With an ER above 0.25, some product gases are also burnt,

increasing the temperature.

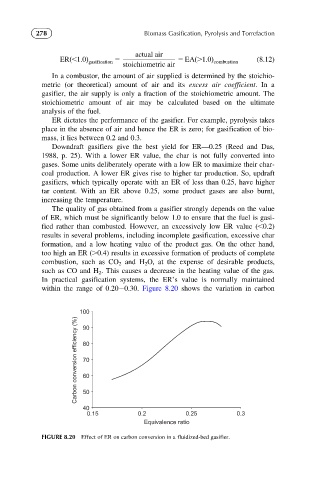

The quality of gas obtained from a gasifier strongly depends on the value

of ER, which must be significantly below 1.0 to ensure that the fuel is gasi-

fied rather than combusted. However, an excessively low ER value (,0.2)

results in several problems, including incomplete gasification, excessive char

formation, and a low heating value of the product gas. On the other hand,

too high an ER (.0.4) results in excessive formation of products of complete

combustion, such as CO 2 and H 2 O, at the expense of desirable products,

such as CO and H 2 . This causes a decrease in the heating value of the gas.

In practical gasification systems, the ER’s value is normally maintained

within the range of 0.20 0.30. Figure 8.20 shows the variation in carbon

100

Carbon conversion efficiency (%) 80

90

70

60

50

40

0.15 0.2 0.25 0.3

Equivalence ratio

FIGURE 8.20 Effect of ER on carbon conversion in a fluidized-bed gasifier.