Page 297 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 297

Chapter | 8 Design of Biomass Gasifiers 273

Pyrolysis gas + tar Oxygen Ash + char

Biomass

Combustion

Gasifier (stage 2)

(stage 3)

Air

Cooler

Low-temperature

gasifier (stage 1) Pulverizer

Product gas

Deduster

Ash

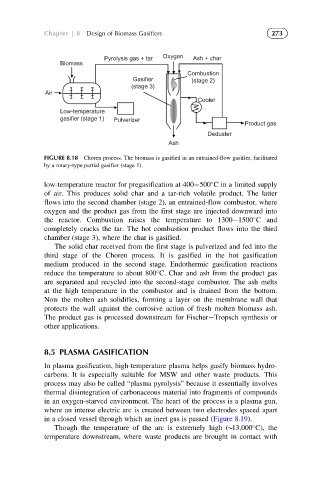

FIGURE 8.18 Choren process. The biomass is gasified in an entrained-flow gasifier, facilitated

by a rotary-type partial gasifier (stage 1).

low-temperature reactor for pregasification at 400 500 C in a limited supply

of air. This produces solid char and a tar-rich volatile product. The latter

flows into the second chamber (stage 2), an entrained-flow combustor, where

oxygen and the product gas from the first stage are injected downward into

the reactor. Combustion raises the temperature to 1300 1500 C and

completely cracks the tar. The hot combustion product flows into the third

chamber (stage 3), where the char is gasified.

The solid char received from the first stage is pulverized and fed into the

third stage of the Choren process. It is gasified in the hot gasification

medium produced in the second stage. Endothermic gasification reactions

reduce the temperature to about 800 C. Char and ash from the product gas

are separated and recycled into the second-stage combustor. The ash melts

at the high temperature in the combustor and is drained from the bottom.

Now the molten ash solidifies, forming a layer on the membrane wall that

protects the wall against the corrosive action of fresh molten biomass ash.

The product gas is processed downstream for Fischer Tropsch synthesis or

other applications.

8.5 PLASMA GASIFICATION

In plasma gasification, high-temperature plasma helps gasify biomass hydro-

carbons. It is especially suitable for MSW and other waste products. This

process may also be called “plasma pyrolysis” because it essentially involves

thermal disintegration of carbonaceous material into fragments of compounds

in an oxygen-starved environment. The heart of the process is a plasma gun,

where an intense electric arc is created between two electrodes spaced apart

in a closed vessel through which an inert gas is passed (Figure 8.19).

Though the temperature of the arc is extremely high (B13,000 C), the

temperature downstream, where waste products are brought in contact with