Page 168 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 168

DESIGN OF ARTIFICIAL KIDNEYS 147

2. The device should be efficient in removing nitrogen, and other waste material and toxic products

of metabolism. It should also remove excess ionic species. The device should efficiently remove

toxic middle molecules.

3. The device should have small priming volume. The priming volume is the volume of the artificial-

kidney–occupied blood. This amount of blood is lost in every dialysis session. Therefore, the

priming volume should be small. The normal blood volume in adult is approximately 5 L.

Therefore, the priming volume should not exceed 250 mL corresponding to 5 percent of the blood

volume. It should be noted that the blood volume in children is much lower.

4. The device should be reliable.

5.3 LOW FLUX VERSUS HIGH FLUX DIALYSIS

Hemodialysis involves the transfer of solutes and water from the blood to the dialysate fluid through

a semipermeable membrane. In the conventional or low flux dialysis, the solutes are removed by dif-

fusion across the semipermeable membrane, and minute quantity of water is removed by using slight

pressure across the membrane. The membrane in low flux dialysis usually has low water permeabil-

ity such that an ultrafiltration controller is not needed to prevent excess water loss from the patient.

On the other hand, membranes used in high flux dialysis have high water permeability, and the

solutes are removed by diffusion and convection. While diffusion depends on the concentration gra-

dient and the solute permeability of the membrane, convection depends on the membrane sieving

7

coefficient, water permeability, and the transmural pressure gradient. Solute transfer flux (dW) for

a differential length can be expressed as

dW = dW diffusion + dW convection

dW = k ×ΔC × dA + S × k × (ΔP – Δπ) × C × dA (5.1)

D U

where dA = the membrane surface area for a differential length along the membrane

C = the concentration of the solute in the blood

ΔC = the concentration difference across the membrane

k = the solute permeability for the membrane

D

k = the ultrafiltration coefficient

U

ΔP = the pressure drop across the membrane

Δπ = the osmotic pressure gradient

S = the sieving coefficient

The ultrafiltration coefficient (k ) for high flux dialyzers is typically in the range of 20 to

U

50 mL/h/mmHg. With convective removal of the middle molecules, there is a significant water loss.

Saline (make-up solution of water and essential nutrients) is infused into the patient along with

the cleaned (dialyzed) blood. Therefore, these high flux dialyzers require precise ultrafiltration

control. The ultrafiltration coefficient is generally in the range of 15 to 30 mL/h/mmHg. 18–20 The

U.S. FDA defines high flux hemodialyzers as those with an ultrafiltration coefficient k greater than

U

12 mL/h/mmHg.

The sieving coefficient (S) and the solute permeability (k ) depend on the ratio of solute radius to

D

pore radius. The solute permeability (k ) drastically decreases with increasing solute radius. The sieving

D

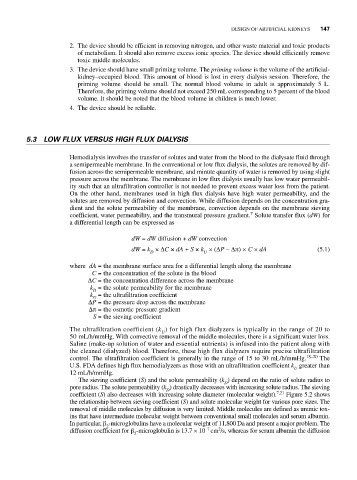

coefficient (S) also decreases with increasing solute diameter (molecular weight). 7,21 Figure 5.2 shows

the relationship between sieving coefficient (S) and solute molecular weight for various pore sizes. The

removal of middle molecules by diffusion is very limited. Middle molecules are defined as uremic tox-

ins that have intermediate molecular weight between conventional small molecules and serum albumin.

In particular, β -microglobulins have a molecular weight of 11,800 Da and present a major problem. The

2

–7

2

diffusion coefficient for β -microglobulin is 13.7 × 10 cm /s, whereas for serum albumin the diffusion

2