Page 186 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 186

DESIGN OF CONTROLLED-RELEASE DRUG DELIVERY SYSTEMS 165

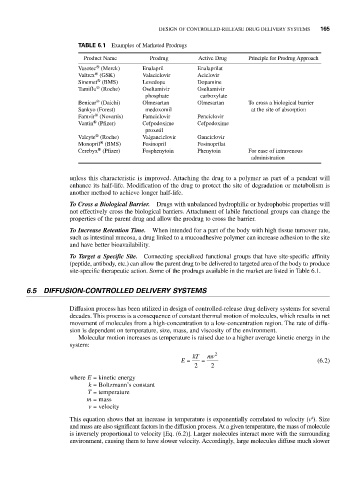

TABLE 6.1 Examples of Marketed Prodrugs

Product Name Prodrug Active Drug Principle for Prodrug Approach

®

Vasotec (Merck) Enalapril Enalaprilat

®

Valtrex (GSK) Valaciclovir Aciclovir

®

Sinemet (BMS) Levedopa Dopamine

®

Tamiflu (Roche) Oseltamivir Oseltamivir

phosphate carboxylate

®

Benicar (Daichi) Olmesartan Olmesartan To cross a biological barrier

Sankyo (Forest) medoxomil at the site of absorption

®

Famvir (Novartis) Famciclovir Penciclovir

®

Vantin (Pfizer) Cefpodoxime Cefpodoxime

proxetil

®

Valcyte (Roche) Valganciclovir Ganciclovir

®

Monopril (BMS) Fosinopril Fosinoprilat

®

Cerebyx (Pfizer) Fosphenytoin Phenytoin For ease of intravenous

administration

unless this characteristic is improved. Attaching the drug to a polymer as part of a pendent will

enhance its half-life. Modification of the drug to protect the site of degradation or metabolism is

another method to achieve longer half-life.

To Cross a Biological Barrier. Drugs with unbalanced hydrophilic or hydrophobic properties will

not effectively cross the biological barriers. Attachment of labile functional groups can change the

properties of the parent drug and allow the prodrug to cross the barrier.

To Increase Retention Time. When intended for a part of the body with high tissue turnover rate,

such as intestinal mucosa, a drug linked to a mucoadhesive polymer can increase adhesion to the site

and have better bioavailability.

To Target a Specific Site. Connecting specialized functional groups that have site-specific affinity

(peptide, antibody, etc.) can allow the parent drug to be delivered to targeted area of the body to produce

site-specific therapeutic action. Some of the prodrugs available in the market are listed in Table 6.1.

6.5 DIFFUSION-CONTROLLED DELIVERY SYSTEMS

Diffusion process has been utilized in design of controlled-release drug delivery systems for several

decades. This process is a consequence of constant thermal motion of molecules, which results in net

movement of molecules from a high-concentration to a low-concentration region. The rate of diffu-

sion is dependent on temperature, size, mass, and viscosity of the environment.

Molecular motion increases as temperature is raised due to a higher average kinetic energy in the

system:

kT mv 2

E = = (6.2)

2 2

where E = kinetic energy

k = Boltzmann’s constant

T = temperature

m = mass

v = velocity

2

This equation shows that an increase in temperature is exponentially correlated to velocity (v ). Size

and mass are also significant factors in the diffusion process. At a given temperature, the mass of molecule

is inversely proportional to velocity [Eq. (6.2)]. Larger molecules interact more with the surrounding

environment, causing them to have slower velocity. Accordingly, large molecules diffuse much slower