Page 221 - Biomimetics : Biologically Inspired Technologies

P. 221

Bar-Cohen : Biomimetics: Biologically Inspired Technologies DK3163_c007 Final Proof page 207 21.9.2005 11:41am

Bio-Nanorobotics 207

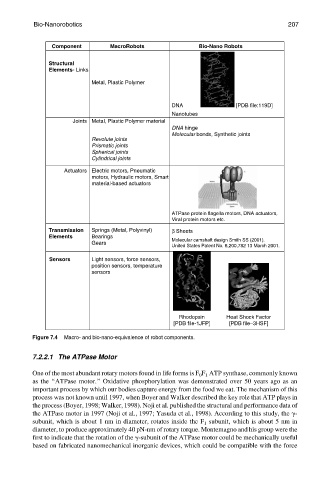

Component MacroRobots Bio-Nano Robots

Structural

Elements- Links

Metal, Plastic Polymer

DNA [PDB file:119D]

Nanotubes

Joints Metal, Plastic Polymer material

DNA hinge

Molecular bonds, Synthetic joints

Revolute joints

Prismatic joints

Spherical joints

Cylindrical joints

Actuators Electric motors, Pneumatic

motors, Hydraulic motors, Smart

material-based actuators

ATPase protein flagella motors, DNA actuators,

Viral protein motors etc.

Transmission Springs (Metal, Polyvinyl) β Sheets

Elements Bearings Molecular camshaft design Smith SS (2001).

Gears

United States Patent No. 6,200,782 13 March 2001.

Sensors Light sensors, force sensors,

position sensors, temperature

sensors

Rhodopsin Heat Shock Factor

[PDB file-1JFP] [PDB file–3HSF]

Figure 7.4 Macro- and bio-nano-equivalence of robot components.

7.2.2.1 The ATPase Motor

One of the most abundant rotary motors found in life forms is F 0 F 1 ATP synthase, commonly known

as the ‘‘ATPase motor.’’ Oxidative phosphorylation was demonstrated over 50 years ago as an

important process by which our bodies capture energy from the food we eat. The mechanism of this

process was not known until 1997, when Boyer and Walker described the key role that ATP plays in

the process (Boyer, 1998; Walker, 1998). Noji et al. published the structural and performance data of

the ATPase motor in 1997 (Noji et al., 1997; Yasuda et al., 1998). According to this study, the g-

subunit, which is about 1 nm in diameter, rotates inside the F 1 subunit, which is about 5 nm in

diameter, to produce approximately 40 pN-nm of rotary torque. Montemagno and his group were the

first to indicate that the rotation of the g-subunit of the ATPase motor could be mechanically useful

based on fabricated nanomechanical inorganic devices, which could be compatible with the force