Page 283 - Biomimetics : Biologically Inspired Technologies

P. 283

Bar-Cohen : Biomimetics: Biologically Inspired Technologies DK3163_c010 Final Proof page 269 21.9.2005 11:46am

Artificial Muscles Using EAP 269

were discovered over half-a-century ago when collagen filaments were demonstrated to revers-

ibly contract or expand upon dipping into acidic or alkaline aqueous solutions, respectively

(Katchalsky, 1949). Even though relatively little has since been done to apply such ‘‘chemo-

mechanical’’ as practical actuators, this early work pioneered the development of synthetic poly-

mers that mimic biological muscles (Steinberg et al., 1966). The convenience and practicality

of electrical stimulation, and technology progress led to a growing interest in EAP materials.

Following the 1969 observation of a substantial piezoelectric activity in polyvinylidene fluoride

(PVDF) (Bar-Cohen et al., 1996; Zhang et al., 1998), investigators started to examine other

polymer systems, and a series of effective materials have emerged. The largest progress in EAP

materials development has been reported in the last 15 years (Bar-Cohen, 2001, 2004) where

materials that can create linear strains that can reach up to 380% have been developed (Pelrine

et al., 2000; Kornbluh et al., 2004).

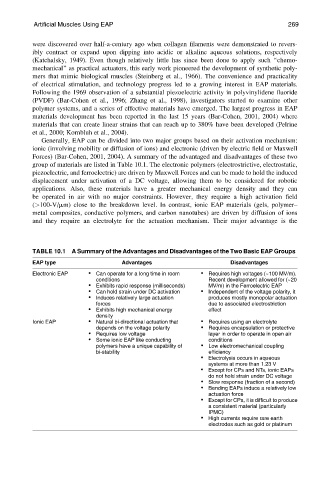

Generally, EAP can be divided into two major groups based on their activation mechanism:

ionic (involving mobility or diffusion of ions) and electronic (driven by electric field or Maxwell

Forces) (Bar-Cohen, 2001, 2004). A summary of the advantaged and disadvantages of these two

group of materials are listed in Table 10.1. The electronic polymers (electrostrictive, electrostatic,

piezoelectric, and ferroelectric) are driven by Maxwell Forces and can be made to hold the induced

displacement under activation of a DC voltage, allowing them to be considered for robotic

applications. Also, these materials have a greater mechanical energy density and they can

be operated in air with no major constraints. However, they require a high activation field

(>100-V/mm) close to the breakdown level. In contrast, ionic EAP materials (gels, polymer–

metal composites, conductive polymers, and carbon nanotubes) are driven by diffusion of ions

and they require an electrolyte for the actuation mechanism. Their major advantage is the

TABLE 10.1 A Summary of the Advantages and Disadvantages of the Two Basic EAP Groups

EAP type Advantages Disadvantages

Electronic EAP . Can operate for a long time in room . Requires high voltages (~100 MV/m).

conditions Recent development allowed for (~20

. Exhibits rapid response (milliseconds) MV/m) in the Ferroelectric EAP

. Can hold strain under DC activation . Independent of the voltage polarity, it

. Induces relatively large actuation produces mostly monopolar actuation

forces due to associated electrostriction

. Exhibits high mechanical energy effect

density

Ionic EAP . Natural bi-directional actuation that . Requires using an electrolyte

depends on the voltage polarity . Requires encapsulation or protective

. Requires low voltage layer in order to operate in open air

. Some ionic EAP like conducting conditions

polymers have a unique capability of . Low electromechanical coupling

bi-stability efficiency

. Electrolysis occurs in aqueous

systems at more than 1.23 V

. Except for CPs and NTs, ionic EAPs

do not hold strain under DC voltage

. Slow response (fraction of a second)

. Bending EAPs induce a relatively low

actuation force

. Except for CPs, it is difficult to produce

a consistent material (particularly

IPMC)

. High currents require rare earth

electrodes such as gold or platinum