Page 284 - Biomimetics : Biologically Inspired Technologies

P. 284

Bar-Cohen : Biomimetics: Biologically Inspired Technologies DK3163_c010 Final Proof page 270 21.9.2005 11:46am

270 Biomimetics: Biologically Inspired Technologies

requirement for drive voltages as low as 1 to 2 V. However, it is necessary to maintain wetness, and

except for conductive polymers and carbon nanotubes it is difficult to sustain DC-induced dis-

placements. The induced displacement of both the electronic and ionic EAP can be geometrically

designed to bend, stretch, or contract. Any of the existing EAP materials can be made to bend with a

significant curving response, offering actuators with an easy to see reaction and an appealing

response. However, bending actuators have relatively limited applications due to the low force or

torque that can be induced.

10.3 TYPES OF ELECTROACTIVE POLYMERS

The types of EAP in each of the two material groups are given below:

10.3.1 Electronic EAP

The electronic types of EAP consist of materials that are squeezed by the attraction force between

the charged electrodes. Some materials in this group are internally affected to augment the

squeezing effect. The dielectric elastomer sustains a deformation under the stress induced by the

electric field driven by Maxwell Forces (Zhang et al., 2004). The other type of electronic EAP

materials is internally active and sustains realignment of the molecular structure (e.g., pendant

group on a backbone chain) or shift of atoms in the crystallographic structure in response to the

field. The electronic type of EAP materials include:

10.3.1.1 Dielectric Elastomer EAP

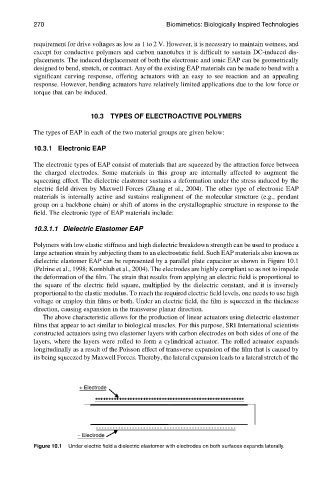

Polymers with low elastic stiffness and high dielectric breakdown strength can be used to produce a

large actuation strain by subjecting them to an electrostatic field. Such EAP materials also known as

dielectric elastomer EAP can be represented by a parallel plate capacitor as shown in Figure 10.1

(Pelrine et al., 1998; Kornbluh et al., 2004). The electrodes are highly compliant so as not to impede

the deformation of the film. The strain that results from applying an electric field is proportional to

the square of the electric field square, multiplied by the dielectric constant, and it is inversely

proportional to the elastic modulus. To reach the required electric field levels, one needs to use high

voltage or employ thin films or both. Under an electric field, the film is squeezed in the thickness

direction, causing expansion in the transverse planar direction.

The above characteristic allows for the production of linear actuators using dielectric elastomer

films that appear to act similar to biological muscles. For this purpose, SRI International scientists

constructed actuators using two elastomer layers with carbon electrodes on both sides of one of the

layers, where the layers were rolled to form a cylindrical actuator. The rolled actuator expands

longitudinally as a result of the Poisson effect of transverse expansion of the film that is caused by

its being squeezed by Maxwell Forces. Thereby, the lateral expansion leads to a lateral stretch of the

+ Electrode

− Electrode

Figure 10.1 Under electric field a dielectric elastomer with electrodes on both surfaces expands laterally.