Page 351 - Biosystems Engineering

P. 351

328 Cha pte r Ele v e n

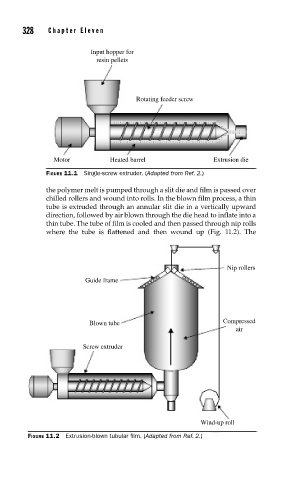

Input hopper for

resin pellets

Rotating feeder screw

Motor Heated barrel Extrusion die

FIGURE 11.1 Single-screw extruder. (Adapted from Ref. 2.)

the polymer melt is pumped through a slit die and film is passed over

chilled rollers and wound into rolls. In the blown film process, a thin

tube is extruded through an annular slit die in a vertically upward

direction, followed by air blown through the die head to inflate into a

thin tube. The tube of film is cooled and then passed through nip rolls

where the tube is flattened and then wound up (Fig. 11.2). The

Nip rollers

Guide frame

Blown tube Compressed

air

Screw extruder

Wind-up roll

FIGURE 11.2 Extrusion-blown tubular fi lm. (Adapted from Ref. 2.)