Page 352 - Biosystems Engineering

P. 352

Food Package Engineering 329

mechanical properties of blown film are generally better because

molecular orientation is achieved in both machine and transverse

directions. The stretching of film is controlled by adjusting the air

pressure inside the tube and haul-off speed. The expansion ratio

between die and blown film is 1.5:4 times the die diameter. The cost

for making a wide tubular film is much lower than for a wide cast

film due to the cost of precision grinding long chill rolls. However,

blown films may contain such defects as variations in film thicknesses,

surface defects, low tensile and impact strengths, and inferior optical

properties. Cast film extrusion results in less thickness variation, very

high outputs, and superior optical properties. Low-density polyeth-

ylene (LDPE) and high-density polyethylene (HDPE) are the most

commonly used polymers for making blown films. The multilayer

structure is obtained using multiple extruders; this process is known

as coextrusion. 2,6

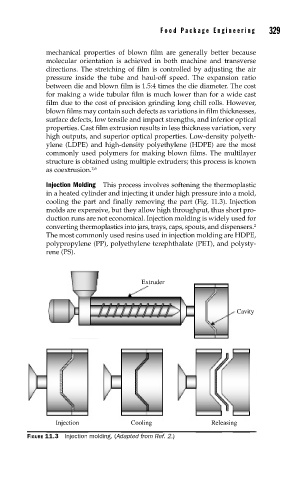

Injection Molding This process involves softening the thermoplastic

in a heated cylinder and injecting it under high pressure into a mold,

cooling the part and finally removing the part (Fig. 11.3). Injection

molds are expensive, but they allow high throughput, thus short pro-

duction runs are not economical. Injection molding is widely used for

converting thermoplastics into jars, trays, caps, spouts, and dispensers. 2

The most commonly used resins used in injection molding are HDPE,

polypropylene (PP), polyethylene terephthalate (PET), and polysty-

rene (PS).

Extruder

Cavity

Injection Cooling Releasing

FIGURE 11.3 Injection molding. (Adapted from Ref. 2.)