Page 416 - Biosystems Engineering

P. 416

Phenolic Substances fr om Olives & Olive Mill Pr oducts 393

“Virgin olive oil” is the oil extracted exclusively with mechanical

techniques; when one virgin olive oil has specific chemical-analytical

and good organoleptic characteristics, it can be sold as extra-virgin,

which indicates that it is of superior quality (UE Regulation 2003).

The olive oil industry also produces a large amount of by-products.

It is estimated that for every 100 kg of olives worked, 35 kg of solid

waste (olive cake or pomace) and variable quantities of liquid waste-

waters are produced. The volume of wastewaters could range from

40 to 100 L for every 100 kg of olives, depending on the oil-extraction

process used.

Pomace contains residue oil and so, it can be processed further to

extract “pomace oil” with husks or kernel wood as additional by-

products.

Other olive mill by-products are the leaves, which represent 5 percent

of the weight of olives worked.

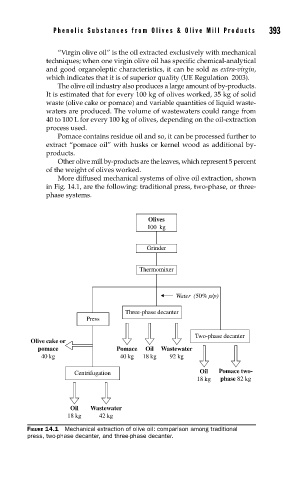

More diffused mechanical systems of olive oil extraction, shown

in Fig. 14.1, are the following: traditional press, two-phase, or three-

phase systems.

Olives

100 kg

Grinder

Thermomixer

Water (50% p/p)

Three-phase decanter

Press

Two-phase decanter

Olive cake or

pomace Pomace Oil Wastewater

40 kg 40 kg 18 kg 92 kg

Centrifugation Oil Pomace two-

18 kg phase 82 kg

Oil Wastewater

18 kg 42 kg

FIGURE 14.1 Mechanical extraction of olive oil: comparison among traditional

press, two-phase decanter, and three-phase decanter.