Page 111 - Boiler_Operators_Handbook,_Second_Edition

P. 111

96 Boiler Operator’s Handbook

should be protected from contact

with air so it should be flooded.

I recommend the installation of

an expansion tank on the boiler

to maintain a flooded condition.

The expansion of the water can

be determined from values in

the steam tables, the difference

between dry and flooded weight

of the boiler, and the normal

range of boiler plant tempera-

tures (40°F to 135°F) to size the

expansion tank. A tank with a

capacity of 3% of the boiler (in

gallons) should work in most

situations. Best is a bladder tank

connected to a branch connection

off the boiler vent with another

vent valve to bleed water when

chemicals have to be added or

the pressure adjusted. Starting

with a tank drained of air until

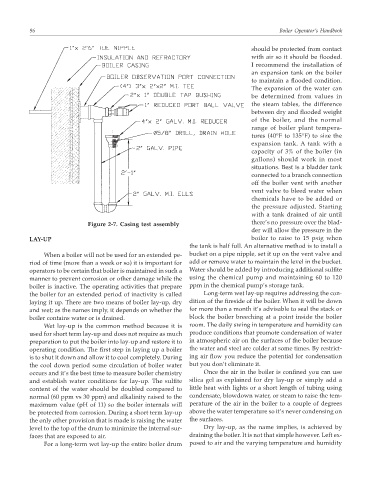

Figure 2-7. Casing test assembly there’s no pressure over the blad-

der will allow the pressure in the

LAY-UP boiler to raise to 15 psig when

the tank is half full. An alternative method is to install a

When a boiler will not be used for an extended pe- bucket on a pipe nipple, set it up on the vent valve and

riod of time (more than a week or so) it is important for add or remove water to maintain the level in the bucket.

operators to be certain that boiler is maintained in such a Water should be added by introducing additional sulfite

manner to prevent corrosion or other damage while the using the chemical pump and maintaining 60 to 120

boiler is inactive. The operating activities that prepare ppm in the chemical pump’s storage tank.

the boiler for an extended period of inactivity is called Long-term wet lay-up requires addressing the con-

laying it up. There are two means of boiler lay-up, dry dition of the fireside of the boiler. When it will be down

and wet; as the names imply, it depends on whether the for more than a month it’s advisable to seal the stack or

boiler contains water or is drained. block the boiler breeching at a point inside the boiler

Wet lay-up is the common method because it is room. The daily swing in temperature and humidity can

used for short term lay-up and does not require as much produce conditions that promote condensation of water

preparation to put the boiler into lay-up and restore it to in atmospheric air on the surfaces of the boiler because

operating condition. The first step in laying up a boiler the water and steel are colder at some times. By restrict-

is to shut it down and allow it to cool completely. During ing air flow you reduce the potential for condensation

the cool down period some circulation of boiler water but you don’t eliminate it.

occurs and it’s the best time to measure boiler chemistry Once the air in the boiler is confined you can use

and establish water conditions for lay-up. The sulfite silica gel as explained for dry lay-up or simply add a

content of the water should be doubled compared to little heat with lights or a short length of tubing using

normal (60 ppm vs 30 ppm) and alkalinity raised to the condensate, blowdown water, or steam to raise the tem-

maximum value (pH of 11) so the boiler internals will perature of the air in the boiler to a couple of degrees

be protected from corrosion. During a short term lay-up above the water temperature so it’s never condensing on

the only other provision that is made is raising the water the surfaces.

level to the top of the drum to minimize the internal sur- Dry lay-up, as the name implies, is achieved by

faces that are exposed to air. draining the boiler. It is not that simple however. Left ex-

For a long-term wet lay-up the entire boiler drum posed to air and the varying temperature and humidity