Page 236 - Boiler_Operators_Handbook,_Second_Edition

P. 236

Maintenance 221

be removed.

Once you’ve removed the tube you should “dress

up” the hole, removing any tube metal stuck to it and

any corrosion that would accompany a leak or defective

rolled joint. Careful use of a file and sandpaper should

produce a smooth surface. The edges of the holes should

also be smoothed over to eliminate any sharp edges

that will cut the new tube. The tube ends should also be

dressed up to remove any corrosion for a tight metal to

metal fit.

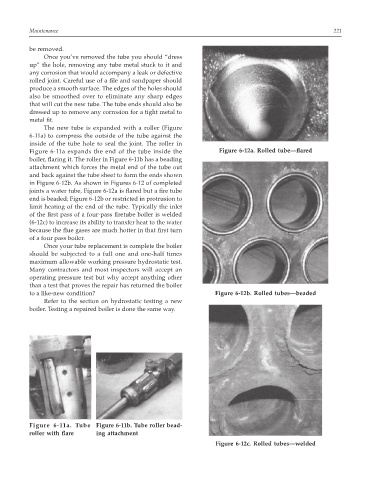

The new tube is expanded with a roller (Figure

6-11a) to compress the outside of the tube against the

inside of the tube hole to seal the joint. The roller in

Figure 6-11a expands the end of the tube inside the Figure 6-12a. Rolled tube—flared

boiler, flaring it. The roller in Figure 6-11b has a beading

attachment which forces the metal end of the tube out

and back against the tube sheet to form the ends shown

in Figure 6-12b. As shown in Figures 6-12 of completed

joints a water tube, Figure 6-12a is flared but a fire tube

end is beaded; Figure 6-12b or restricted in protrusion to

limit heating of the end of the tube. Typically the inlet

of the first pass of a four-pass firetube boiler is welded

(6-12c) to increase its ability to transfer heat to the water

because the flue gases are much hotter in that first turn

of a four pass boiler.

Once your tube replacement is complete the boiler

should be subjected to a full one and one-half times

maximum allowable working pressure hydrostatic test.

Many contractors and most inspectors will accept an

operating pressure test but why accept anything other

than a test that proves the repair has returned the boiler

to a like-new condition? Figure 6-12b. Rolled tubes—beaded

Refer to the section on hydrostatic testing a new

boiler. Testing a repaired boiler is done the same way.

Figure 6-11a. Tube Figure 6-11b. Tube roller bead-

roller with flare ing attachment

Figure 6-12c. Rolled tubes—welded