Page 238 - Boiler_Operators_Handbook,_Second_Edition

P. 238

Maintenance 223

buy the product at his low prices. He was told thanks, The tack welds should all be checked to be sure none of

but no thanks and I’ve been very conscious of what I was them are cracked; a light tap with a hammer will nor-

buying thereafter. As far as I’m concerned any pipe that mally produce a ringing sound, any static is indicative

goes into a boiler room should have a stencil running of a crack that can’t be seen without magnification or

repeatedly along its length that begins “ANSI” and for other testing. Some procedures require the tack welds

B31.1 piping also “ASME” followed by a specification be replaced as the root pass is made but the tacks are

number and other data including a heat number which normally incorporated into the root pass.

makes the material traceable to the piping manufacturer.

Pipe fittings and valves must bear certain markings but

certificates aren’t required. They should, however, bear

a marking that identifies the manufacturer and the ap-

propriate ANSI specification.

As for the welder, the only way to determine the

quality without requiring RT (radiation testing, fre-

quently called X-ray) is visual examination by someone

who knows what to look for. Here’s what to look for:

Fit-up

The fit-up consists of matching the joint between

two pieces of pipe or a pipe and fitting or weld end

valve and attaching them with tack welds at no fewer

than four points evenly spaced around the pipe. The

two ends should be ground clean to gray metal (no rust,

paint, oil or other coating) for at least one-half inch from

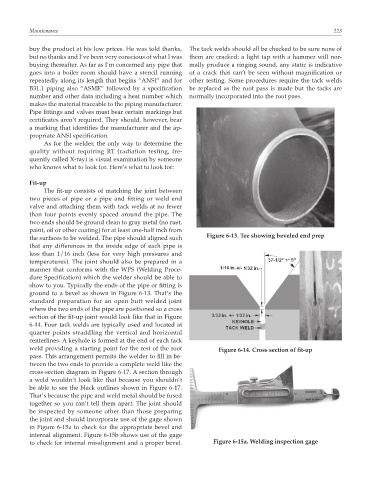

Figure 6-13. Tee showing beveled end prep

the surfaces to be welded. The pipe should aligned such

that any differences in the inside edge of each pipe is

less than 1/16 inch (less for very high pressures and

temperatures). The joint should also be prepared in a

manner that conforms with the WPS (Welding Proce-

dure Specification) which the welder should be able to

show to you. Typically the ends of the pipe or fitting is

ground to a bevel as shown in Figure 6-13. That’s the

standard preparation for an open butt welded joint

where the two ends of the pipe are positioned so a cross

section of the fit-up joint would look like that in Figure

6-14. Four tack welds are typically used and located at

quarter points straddling the vertical and horizontal

centerlines. A keyhole is formed at the end of each tack

weld providing a starting point for the rest of the root Figure 6-14. Cross section of fit-up

pass. This arrangement permits the welder to fill in be-

tween the two ends to provide a complete weld like the

cross-section diagram in Figure 6-17. A section through

a weld wouldn’t look like that because you shouldn’t

be able to see the black outlines shown in Figure 6-17.

That’s because the pipe and weld metal should be fused

together so you can’t tell them apart. The joint should

be inspected by someone other than those preparing

the joint and should incorporate use of the gage shown

in Figure 6-15a to check for the appropriate bevel and

internal alignment. Figure 6-15b shows use of the gage

to check for internal misalignment and a proper bevel. Figure 6-15a. Welding inspection gage