Page 119 - Bridge and Highway Structure Rehabilitation and Repair

P. 119

94 SECTION 1 ADMINISTRATIVE ISSUES

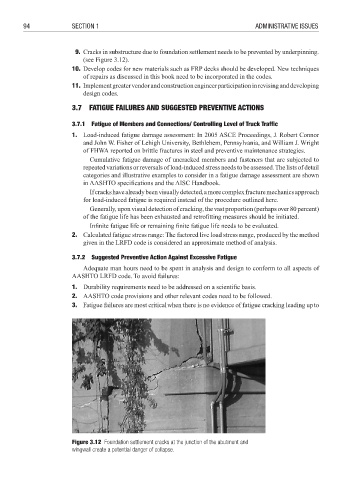

9. Cracks in substructure due to foundation settlement needs to be prevented by underpinning.

(see Figure 3.12).

10. Develop codes for new materials such as FRP decks should be developed. New techniques

of repairs as discussed in this book need to be incorporated in the codes.

11. Implement greater vendor and construction engineer participation in revising and developing

design codes.

3.7 FATIGUE FAILURES AND SUGGESTED PREVENTIVE ACTIONS

3.7.1 Fatigue of Members and Connections/ Controlling Level of Truck Traffi c

1. Load-induced fatigue damage assessment: In 2005 ASCE Proceedings, J. Robert Connor

and John W. Fisher of Lehigh University, Bethlehem, Pennsylvania, and William J. Wright

of FHWA reported on brittle fractures in steel and preventive maintenance strategies.

Cumulative fatigue damage of uncracked members and fasteners that are subjected to

repeated variations or reversals of load-induced stress needs to be assessed. The lists of detail

categories and illustrative examples to consider in a fatigue damage assessment are shown

in AASHTO specifications and the AISC Handbook.

If cracks have already been visually detected, a more complex fracture mechanics approach

for load-induced fatigue is required instead of the procedure outlined here.

Generally, upon visual detection of cracking, the vast proportion (perhaps over 80 percent)

of the fatigue life has been exhausted and retrofitting measures should be initiated.

Infinite fatigue life or remaining finite fatigue life needs to be evaluated.

2. Calculated fatigue stress range: The factored live load stress range, produced by the method

given in the LRFD code is considered an approximate method of analysis.

3.7.2 Suggested Preventive Action Against Excessive Fatigue

Adequate man hours need to be spent in analysis and design to conform to all aspects of

AASHTO LRFD code. To avoid failures:

1. Durability requirements need to be addressed on a scientifi c basis.

2. AASHTO code provisions and other relevant codes need to be followed.

3. Fatigue failures are most criticalwhen there is no evidence of fatigue cracking leading upto

Figure 3.12 Foundation settlement cracks at the junction of the abutment and

wingwall create a potential danger of collapse.