Page 70 - Bridge and Highway Structure Rehabilitation and Repair

P. 70

CHAPTER 2 DIAGNOSTIC DESIGN AND SELECTIVE RECONSTRUCTION 45

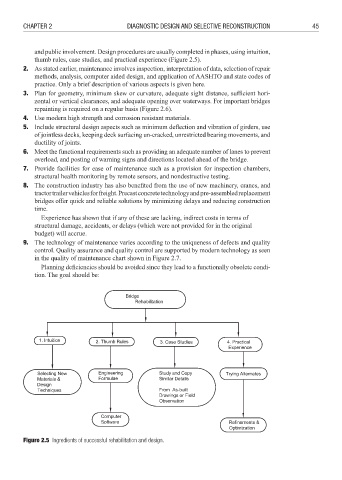

and public involvement. Design procedures are usually completed in phases, using intuition,

thumb rules, case studies, and practical experience (Figure 2.5).

2. As stated earlier, maintenance involves inspection, interpretation of data, selection of repair

methods, analysis, computer aided design, and application of AASHTO and state codes of

practice. Only a brief description of various aspects is given here.

3. Plan for geometry, minimum skew or curvature, adequate sight distance, suffi cient hori-

zontal or vertical clearances, and adequate opening over waterways. For important bridges

repainting is required on a regular basis (Figure 2.6).

4. Use modern high strength and corrosion resistant materials.

5. Include structural design aspects such as minimum deflection and vibration of girders, use

of jointless decks, keeping deck surfacing un-cracked, unrestricted bearing movements, and

ductility of joints.

6. Meet the functional requirements such as providing an adequate number of lanes to prevent

overload, and posting of warning signs and directions located ahead of the bridge.

7. Provide facilities for ease of maintenance such as a provision for inspection chambers,

structural health monitoring by remote sensors, and nondestructive testing.

8. The construction industry has also benefited from the use of new machinery, cranes, and

tractor trailer vehicles for freight. Precast concrete technology and pre-assembled replacement

bridges offer quick and reliable solutions by minimizing delays and reducing construction

time.

Experience has shown that if any of these are lacking, indirect costs in terms of

structural damage, accidents, or delays (which were not provided for in the original

budget) will accrue.

9. The technology of maintenance varies according to the uniqueness of defects and quality

control. Quality assurance and quality control are supported by modern technology as seen

in the quality of maintenance chart shown in Figure 2.7.

Planning deficiencies should be avoided since they lead to a functionally obsolete condi-

tion. The goal should be:

Figure 2.5 Ingredients of successful rehabilitation and design.