Page 68 - Building A Succesful Board-Test Strategy

P. 68

54 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

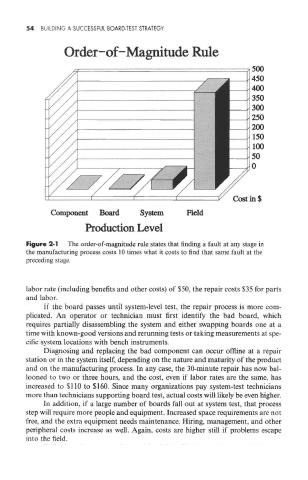

Figure 2-1 The order-of-magnitude rule states that finding a fault at any stage in

the manufacturing process costs 10 times what it costs to find that same fault at the

preceding stage.

labor rate (including benefits and other costs) of $50, the repair costs $35 for parts

and labor.

If the board passes until system-level test, the repair process is more com-

plicated. An operator or technician must first identify the bad board, which

requires partially disassembling the system and either swapping boards one at a

time with known-good versions and rerunning tests or taking measurements at spe-

cific system locations with bench instruments.

Diagnosing and replacing the bad component can occur offline at a repair

station or in the system itself, depending on the nature and maturity of the product

and on the manufacturing process. In any case, the 30-rninute repair has now bal-

looned to two or three hours, and the cost, even if labor rates are the same, has

increased to $110 to $160. Since many organizations pay system-test technicians

more than technicians supporting board test, actual costs will likely be even higher.

In addition, if a large number of boards fall out at system test, that process

step will require more people and equipment. Increased space requirements are not

free, and the extra equipment needs maintenance. Hiring, management, and other

peripheral costs increase as well. Again, costs are higher still if problems escape

into the field.