Page 292 - Buried Pipe Design

P. 292

Rigid Pipe Products 263

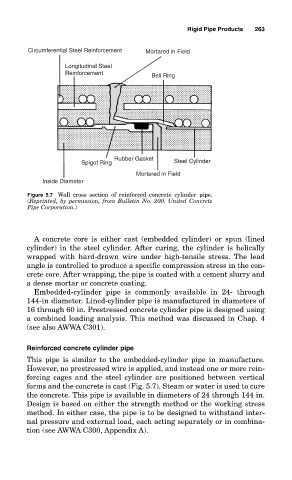

Circumferential Steel Reinforcement Mortared in Field

Longitudinal Steel

Reinforcement Bell Ring

Rubber Gasket

Spigot Ring Steel Cylinder

Mortared in Field

Inside Diameter

Figure 5.7 Wall cross section of reinforced concrete cylinder pipe.

(Reprinted, by permission, from Bulletin No. 200, United Concrete

Pipe Corporation.)

A concrete core is either cast (embedded cylinder) or spun (lined

cylinder) in the steel cylinder. After curing, the cylinder is helically

wrapped with hard-drawn wire under high-tensile stress. The lead

angle is controlled to produce a specific compression stress in the con-

crete core. After wrapping, the pipe is coated with a cement slurry and

a dense mortar or concrete coating.

Embedded-cylinder pipe is commonly available in 24- through

144-in diameter. Lined-cylinder pipe is manufactured in diameters of

16 through 60 in. Prestressed concrete cylinder pipe is designed using

a combined loading analysis. This method was discussed in Chap. 4

(see also AWWA C301).

Reinforced concrete cylinder pipe

This pipe is similar to the embedded-cylinder pipe in manufacture.

However, no prestressed wire is applied, and instead one or more rein-

forcing cages and the steel cylinder are positioned between vertical

forms and the concrete is cast (Fig. 5.7). Steam or water is used to cure

the concrete. This pipe is available in diameters of 24 through 144 in.

Design is based on either the strength method or the working stress

method. In either case, the pipe is to be designed to withstand inter-

nal pressure and external load, each acting separately or in combina-

tion (see AWWA C300, Appendix A).