Page 297 - Buried Pipe Design

P. 297

268 Chapter Five

■ The area of bar reinforcement in square inches per linear foot of

pipe wall shall be numerically equal to at least 1 percent of the

inside diameter of the pipe, in inches.

■ The design clear space between bars shall not be less than the

diameter of the bar used.

7

■ The bar diameter shall not be less than in.

32

3. Calculate the total external load on the pipe. External loads must

be computed in accordance with recognized and accepted theories,

such as those presented in Chap. 2.

4. Determine if the total external load is less than either the maxi-

mum allowable external load for minimum designs or the maxi-

mum allowable external load for the actual design. If either

condition is met, then the selected pipe design meets the project

requirements.

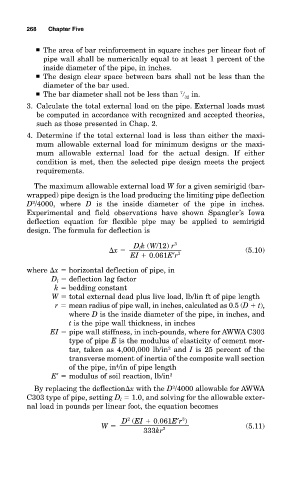

The maximum allowable external load W for a given semirigid (bar-

wrapped) pipe design is the load producing the limiting pipe deflection

D /4000, where D is the inside diameter of the pipe in inches.

2

Experimental and field observations have shown Spangler’s Iowa

deflection equation for flexible pipe may be applied to semirigid

design. The formula for deflection is

D l k (W/12) r 3

x (5.10)

EI 0.061E′r 3

where x horizontal deflection of pipe, in

D l deflection lag factor

k bedding constant

W total external dead plus live load, lb/lin ft of pipe length

r mean radius of pipe wall, in inches, calculated as 0.5 (D t),

where D is the inside diameter of the pipe, in inches, and

t is the pipe wall thickness, in inches

EI pipe wall stiffness, in inch-pounds, where for AWWA C303

type of pipe E is the modulus of elasticity of cement mor-

2

tar, taken as 4,000,000 lb/in and I is 25 percent of the

transverse moment of inertia of the composite wall section

4

of the pipe, in /in of pipe length

E′ modulus of soil reaction, lb/in 2

By replacing the deflection x with the D /4000 allowable for AWWA

2

C303 type of pipe, setting D l 1.0, and solving for the allowable exter-

nal load in pounds per linear foot, the equation becomes

3

2

D (EI 0.061E′r )

W (5.11)

333kr 3