Page 294 - Buried Pipe Design

P. 294

Rigid Pipe Products 265

Cement-Mortar Coating

Prestressed Steel Wire

Mortared in Field

Bell Ring

Spigot Ring

Rubber Gasket Steel Cylinder

Inside Diameter Cement-Mortar Coating Mortared in Field

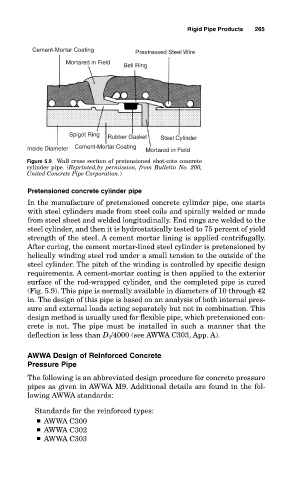

Figure 5.9 Wall cross section of pretensioned shot-cote concrete

cylinder pipe. (Reprinted,by permission, from Bulletin No. 200,

United Concrete Pipe Corporation.)

Pretensioned concrete cylinder pipe

In the manufacture of pretensioned concrete cylinder pipe, one starts

with steel cylinders made from steel coils and spirally welded or made

from steel sheet and welded longitudinally. End rings are welded to the

steel cylinder, and then it is hydrostatically tested to 75 percent of yield

strength of the steel. A cement mortar lining is applied centrifugally.

After curing, the cement mortar-lined steel cylinder is pretensioned by

helically winding steel rod under a small tension to the outside of the

steel cylinder. The pitch of the winding is controlled by specific design

requirements. A cement-mortar coating is then applied to the exterior

surface of the rod-wrapped cylinder, and the completed pipe is cured

(Fig. 5.9). This pipe is normally available in diameters of 10 through 42

in. The design of this pipe is based on an analysis of both internal pres-

sure and external loads acting separately but not in combination. This

design method is usually used for flexible pipe, which pretensioned con-

crete is not. The pipe must be installed in such a manner that the

deflection is less than D 2 /4000 (see AWWA C303, App. A).

AWWA Design of Reinforced Concrete

Pressure Pipe

The following is an abbreviated design procedure for concrete pressure

pipes as given in AWWA M9. Additional details are found in the fol-

lowing AWWA standards:

Standards for the reinforced types:

■ AWWA C300

■ AWWA C302

■ AWWA C303