Page 16 - CNC Robotics

P. 16

CNC Robotics

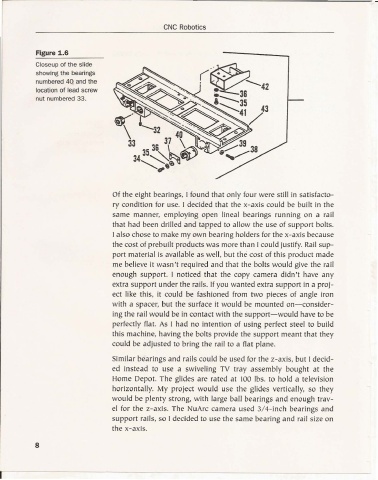

Figure 1.6

Closeup of the slide

showing the bearings

numbered 40 and the

location of lead screw

nut numbered 33 .

Of the eight bearings, I found that only four were still in satisfacto-

ry condition for use. I decided that the x-axis could be built in the

same manner, employing open linea l bearings running on a rail

that had been drilled and tapped to allow the use of support bolts.

I also chose to make my own bearing holders for the x-ax is because

the cost of preb uilt products was more than Icould justify. Rail sup-

port material is ava ilable as well, but the cost of this product made

me believe it wasn't required and that the bolts wo uld give the rail

enough su pport. I noti ced that the copy camera didn't have any

extra support under the rails. If you wanted extra support in a pro j-

ect like this, it co uld be fashioned from two pieces of angle iron

with a spacer, but the su rface it would be mounted on-consider-

ing the rail would be in con tact with the support-would have to be

perfectly flat. As I had no intention of using perfect steel to bu ild

this machine, having the bolts provide the support meant that they

could be adjusted to bring the rail to a flat plane.

Similar bearings an d rails cou ld be used for the z-axls, but I decid-

ed instead to use a sw iveling TV tray assembly bought at the

Home Depot. The glides are rated at 100 Ibs. to ho ld a televisio n

hori zontally. My project would use the glides vertically, so they

would be plenty strong, with large ba ll bearings an d enough trav-

el for the z-axls. The NuArc ca mera used 3/4-inch bearings and

support rails, so I decided to use the sa me bearing and rail size on

the x-axis.

8

r- - - - - - - - - - - - - - - - - - - - - - - - -