Page 177 - CNC Robotics

P. 177

CNC Robotics

The next hole was drilled from the side of the holder until the

notch was reached. This hole had to be tapped to accommodate

the adj usting screw (see Figure 7.24).

Figure 7.24

Tapping hole for

adjusting screw.

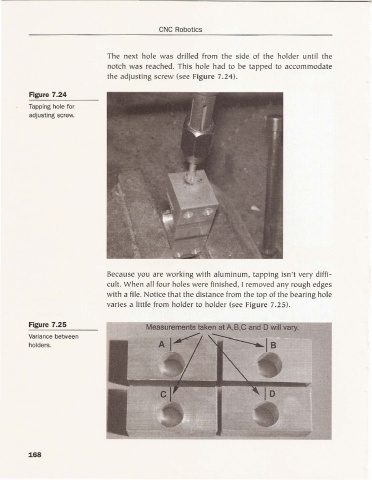

Because you are working w ith alumi num. tapping isn't very diffi-

cult. When all four hol es were finished. I removed any rough edges

w ith a file. Notice that the distance from the top of the bearing hole

varies a little from ho lder to holder (see Figure 7.2 5).

Figure 7.25

Variance between

holders.

168