Page 14 - Cam Design Handbook

P. 14

THB1 8/15/03 2:42 PM Page 2

2 CAM DESIGN HANDBOOK

Valve spring

Valve

linkage

Camshaft

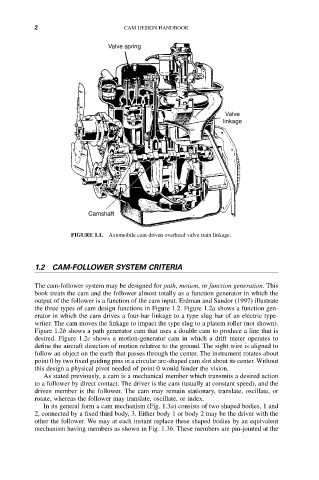

FIGURE 1.1. Automobile cam-driven overhead valve train linkage.

1.2 CAM-FOLLOWER SYSTEM CRITERIA

The cam-follower system may be designed for path, motion, or function generation. This

book treats the cam and the follower almost totally as a function generator in which the

output of the follower is a function of the cam input. Erdman and Sandor (1997) illustrate

the three types of cam design functions in Figure 1.2. Figure 1.2a shows a function gen-

erator in which the cam drives a four-bar linkage to a type slug bar of an electric type-

writer. The cam moves the linkage to impact the type slug to a platem roller (not shown).

Figure 1.2b shows a path generator cam that uses a double cam to produce a line that is

desired. Figure 1.2c shows a motion-generator cam in which a drift meter operates to

define the aircraft direction of motion relative to the ground. The sight wire is aligned to

follow an object on the earth that passes through the center. The instrument rotates about

point 0 by two fixed guiding pins in a circular arc-shaped cam slot about its center. Without

this design a physical pivot needed of point 0 would hinder the vision.

As stated previously, a cam is a mechanical member which transmits a desired action

to a follower by direct contact. The driver is the cam (usually at constant speed), and the

driven member is the follower. The cam may remain stationary, translate, oscillate, or

rotate, whereas the follower may translate, oscillate, or index.

In its general form a cam mechanism (Fig. 1.3a) consists of two shaped bodies, 1 and

2, connected by a fixed third body, 3. Either body 1 or body 2 may be the driver with the

other the follower. We may at each instant replace these shaped bodies by an equivalent

mechanism having members as shown in Fig. 1.3b. These members are pin-jointed at the