Page 185 - Cam Design Handbook

P. 185

THB6 8/15/03 2:40 PM Page 173

ELEMENTS OF CAM PROFILE GEOMETRY 173

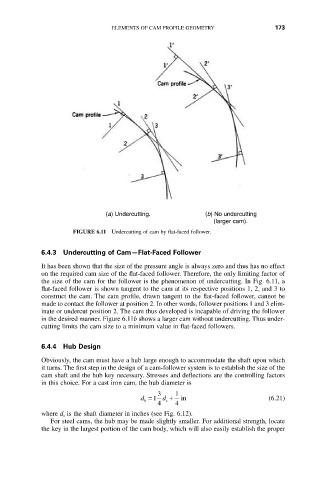

(a) Undercutting. (b) No undercutting

(larger cam).

FIGURE 6.11 Undercutting of cam by flat-faced follower.

6.4.3 Undercutting of Cam—Flat-Faced Follower

It has been shown that the size of the pressure angle is always zero and thus has no effect

on the required cam size of the flat-faced follower. Therefore, the only limiting factor of

the size of the cam for the follower is the phenomenon of undercutting. In Fig. 6.11, a

flat-faced follower is shown tangent to the cam at its respective positions 1, 2, and 3 to

construct the cam. The cam profile, drawn tangent to the flat-faced follower, cannot be

made to contact the follower at position 2. In other words, follower positions 1 and 3 elim-

inate or undercut position 2. The cam thus developed is incapable of driving the follower

in the desired manner. Figure 6.11b shows a larger cam without undercutting. Thus under-

cutting limits the cam size to a minimum value in flat-faced followers.

6.4.4 Hub Design

Obviously, the cam must have a hub large enough to accommodate the shaft upon which

it turns. The first step in the design of a cam-follower system is to establish the size of the

cam shaft and the hub key necessary. Stresses and deflections are the controlling factors

in this choice. For a cast iron cam, the hub diameter is

3 1

d =1 d + in (6.21)

h s

4 4

where d s is the shaft diameter in inches (see Fig. 6.12).

For steel cams, the hub may be made slightly smaller. For additional strength, locate

the key in the largest portion of the cam body, which will also easily establish the proper