Page 184 - Cam Design Handbook

P. 184

THB6 8/15/03 2:40 PM Page 172

172 CAM DESIGN HANDBOOK

R r (b) Sharp point

r k r = R r

k

Pitch curve

Cam profile

r k

(a) Proper action

r > 0

k

(c) Undercutting

r < R r

k

Desired path P k (d ) Proper action

r k r > R r

k

r c

Actual path

(e) Undercutting

Desired path

r < 0

k

Actual path r < R r

c

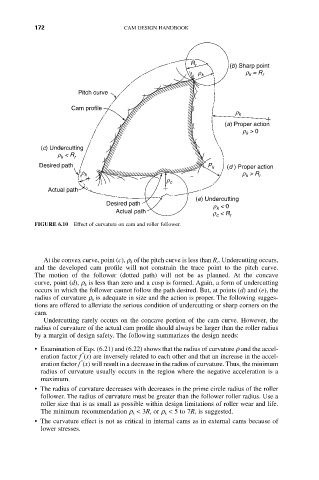

FIGURE 6.10 Effect of curvature on cam and roller follower.

At the convex curve, point (c), r k of the pitch curve is less than R r. Undercutting occurs,

and the developed cam profile will not constrain the trace point to the pitch curve.

The motion of the follower (dotted path) will not be as planned. At the concave

curve, point (d), r k is less than zero and a cusp is formed. Again, a form of undercutting

occurs in which the follower cannot follow the path desired. But, at points (d) and (e), the

radius of curvature r k is adequate in size and the action is proper. The following sugges-

tions are offered to alleviate the serious condition of undercutting or sharp corners on the

cam.

Undercutting rarely occurs on the concave portion of the cam curve. However, the

radius of curvature of the actual cam profile should always be larger than the roller radius

by a margin of design safety. The following summarizes the design needs:

• Examination of Eqs. (6.21) and (6.22) shows that the radius of curvature r and the accel-

≤

eration factor f (x) are inversely related to each other and that an increase in the accel-

≤

eration factor f (x) will result in a decrease in the radius of curvature. Thus, the minimum

radius of curvature usually occurs in the region where the negative acceleration is a

maximum.

• The radius of curvature decreases with decreases in the prime circle radius of the roller

follower. The radius of curvature must be greater than the follower roller radius. Use a

roller size that is as small as possible within design limitations of roller wear and life.

The minimum recommendation r k < 3R r or r k < 5 to 7R r is suggested.

• The curvature effect is not as critical in internal cams as in external cams because of

lower stresses.