Page 277 - Cam Design Handbook

P. 277

THB9 9/19/03 7:26 PM Page 265

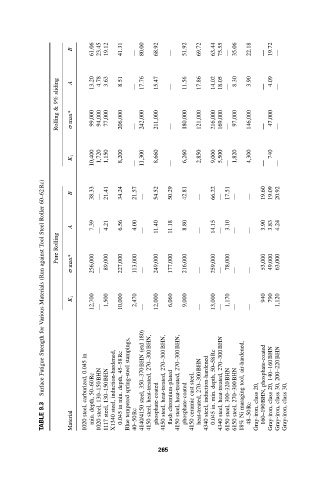

61.06 23.45 19.12 41.31 — 80.00 68.92 — 51.92 69.72 63.44 75.55 — 35.06 22.18 — 19.72 —

B

Rolling & 9% sliding A max* s 13.20 99,000 4.78 94,000 3.63 77,000 8.51 206,000 — — 17.76 242,000 15.47 211,000 — — 11.56 180,000 17.86 121,000 14.02 216,000 18.05 169,000 — — 8.30 97,000 3.90 146,000 — — 4.09 47,000 — —

K 1 10,400 1,720 1,150 8,200 — 11,300 8,660 — 6,260 2,850 9,000 5,500 — 1,820 4,300 — 740 —

Surface Fatigue Strength for Various Materials (Run against Tool Steel Roller 60–62Rc)

38.33 — 21.41 34.24 21.57 — 54.52 50.29 42.81 — 66.22 — 17.51 — — 19.60 19.09 20.92

B

7.39 4.21 6.56 4.00 8.80 3.10 3.90 3.83 4.24

A — — 11.40 11.18 — 14.15 — — —

Pure Rolling

s max* 256,000 — 89,000 227,000 113,000 — 249,000 177,000 216,000 — 259,000 — 78,000 — — 53,000 49,000 63,000

12,700 — 10,000 — 12,000 — 13,000 — — —

K 1 1,500 2,470 6,060 9,000 1,170 940 790 1,120

1020 steel, carburized, 0.045 in min. depth, 50–60Rc 1020 steel, 130–150BHN 1117 steel, 130–150BHN X1340 steel, induction-hardened, 0.045 in min. depth, 45–58Rc Blue tempered spring-steel stampings, 4140/4150 steel, 350–370BHN (etd 180) 4150 steel, heat-treated, 270–300BHN, phosphate-coated 4150 steel, heat-treated,

TABLE 9.3 Material 40–50Rc 48–50Rc Gray-iron, class 20, Gray-iron, class 30,

265