Page 273 - Cam Design Handbook

P. 273

THB9 9/19/03 7:26 PM Page 261

CAM MATERIALS AND LUBRICATION 261

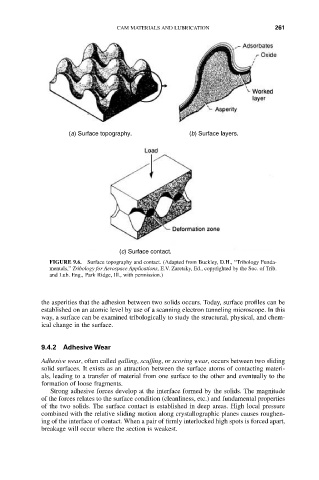

(a) Surface topography. (b) Surface layers.

(c) Surface contact.

FIGURE 9.6. Surface topography and contact. (Adapted from Buckley, D.H., “Tribology Funda-

mentals,” Tribology for Aerospace Applications, E.V. Zaretsky, Ed., copyrighted by the Soc. of Trib.

and Lub. Eng., Park Ridge, Ill., with permission.)

the asperities that the adhesion between two solids occurs. Today, surface profiles can be

established on an atomic level by use of a scanning electron tunneling microscope. In this

way, a surface can be examined tribologically to study the structural, physical, and chem-

ical change in the surface.

9.4.2 Adhesive Wear

Adhesive wear, often called galling, scuffing, or scoring wear, occurs between two sliding

solid surfaces. It exists as an attraction between the surface atoms of contacting materi-

als, leading to a transfer of material from one surface to the other and eventually to the

formation of loose fragments.

Strong adhesive forces develop at the interface formed by the solids. The magnitude

of the forces relates to the surface condition (cleanliness, etc.) and fundamental properties

of the two solids. The surface contact is established in deep areas. High local pressure

combined with the relative sliding motion along crystallographic planes causes roughen-

ing of the interface of contact. When a pair of firmly interlocked high spots is forced apart,

breakage will occur where the section is weakest.