Page 278 - Cam Design Handbook

P. 278

THB9 9/19/03 7:26 PM Page 266

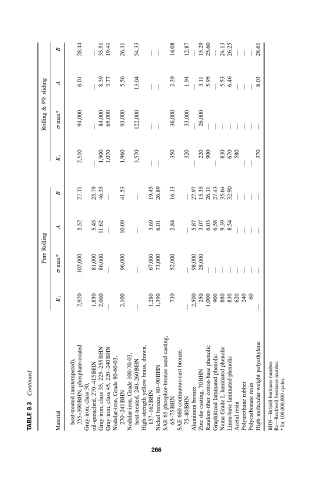

28.44 — 35.51 19.41 26.31 54.33 — — 14.08 12.87 — 15.29 25.60 — 24.13 26.25 — — — 28.61

B

Rolling & 9% sliding A max* 6.01 94,000 — 8.39 84,000 3.77 65,000 5.56 93,000 13.04 122,000 — — 2.39 36,000 1.94 33,000 — 3.11 26,000 5.95 — 5.53 6.46 — — — 8.03

—

—

—

—

830— — 670— 580— — — 370—

—

s

2,510 1,900 1,070 1,960 3,570 350 320 220 900

K 1 — — — — — — —

27.11 25.79 46.35 — 41.53 — 19.45 26.89 16.13 — 27.97 15.35 26.11 27.43 35.64 32.90 — — — —

B

5.52 5.45 3.69 6.01 2.84 5.87 3.07 6.03 6.58 9.39 8.54

A 11.62 — 10.09 — — — — — —

Pure Rolling

880— 830— 620— 240— 60—

s max* 102,000 81,000 86,000 — 96,000 — 67,000 73,000 52,000 — 98,000 28,000 — — —

2,920 1,850 2,000 — 2,100 — 1,280 1,390 — 2,500 1,000 —

K 1 730 250 900 phenolic

phenolic laminated polyethylene

Continued heat-treated (austempered), 255–300BHN, phosphate-coated oil-quenched, 270–415BHN Gray-iron, class 35, 225–255BHN Gray-iron, class 45, 220–240BHN Nodular-iron, Grade 80-60-03, Nodular-iron, Grade 100-70-03, heat-treated, 240–260BHN High-strength yellow brass, drawn, Nickel bronze, 80–90BHN SAE 65 phosphor-bronze sand c

TABLE 9.3 Material Gray-iron, class 30, 270–241BHN 157–162BHN 65–75BHN 75–80BHN Aluminum bronze Zinc die casting, 70BHN Nema Linen-base Acetal Polyurethane Polycarbonate High-molecular-weight *for 100,000,000 cycles.

266