Page 271 - Cam Design Handbook

P. 271

THB9 9/19/03 7:26 PM Page 259

CAM MATERIALS AND LUBRICATION 259

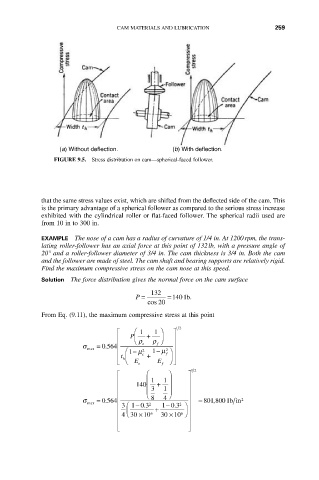

(a) Without deflection. (b) With deflection.

FIGURE 9.5. Stress distribution on cam—spherical-faced follower.

that the same stress values exist, which are shifted from the deflected side of the cam. This

is the primary advantage of a spherical follower as compared to the serious stress increase

exhibited with the cylindrical roller or flat-faced follower. The spherical radii used are

from 10 in to 300 in.

EXAMPLE The nose of a cam has a radius of curvature of 1/4 in. At 1200rpm, the trans-

lating roller-follower has an axial force at this point of 132lb, with a pressure angle of

20° and a roller-follower diameter of 3/4 in. The cam thickness is 3/4 in. Both the cam

and the follower are made of steel. The cam shaft and bearing supports are relatively rigid.

Find the maximum compressive stress on the cam nose at this speed.

Solution The force distribution gives the normal force on the cam surface

132

P = =1401b.

cos 20

From Eq. (9.11), the maximum compressive stress at this point

12

È Ê 1 1 ˆ ˘

Í P Á Ë r + r ¯ ˜ ˙

s = . 0564 Í e f ˙

max 2

Í Ê1 - m 2 1 - m ˆ ˙

f

t c +

Í h Á ˜ ˙

Î Ë E e E f ¯ ˚

12

È Ê ˆ ˘

Í Á 1 1 ˜ ˙

Í 140 Á 3 + 1 ˜ ˙

Í Á Ë ˜ ¯ ˙

s max = . 0564 Í 8 4 ˙ = 801 8001, bin 2

-

-

.

.

Í Í 3 Ê 103 2 103 2 ˆ ˙

Í 4 Á Ë 3010 6 + 3010 6 ˜ ¯ ˙

¥

¥

Í ˙

Í ˙

Î ˚