Page 292 - Cam Design Handbook

P. 292

THB9 9/19/03 7:26 PM Page 280

280 CAM DESIGN HANDBOOK

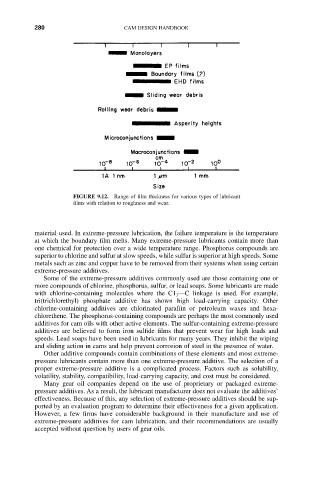

FIGURE 9.12. Range of film thickness for various types of lubricant

films with relation to roughness and wear.

material used. In extreme-pressure lubrication, the failure temperature is the temperature

at which the boundary film melts. Many extreme-pressure lubricants contain more than

one chemical for protection over a wide temperature range. Phosphorus compounds are

superior to chlorine and sulfur at slow speeds, while sulfur is superior at high speeds. Some

metals such as zinc and copper have to be removed from their systems when using certain

extreme-pressure additives.

Some of the extreme-pressure additives commonly used are those containing one or

more compounds of chlorine, phosphorus, sulfur, or lead soaps. Some lubricants are made

with chlorine-containing molecules where the C1 3 —C linkage is used. For example,

tri(trichlorethyl) phosphate additive has shown high load-carrying capacity. Other

chlorine-containing additives are chlorinated paraffin or petroleum waxes and hexa-

chlorethene. The phosphorus-containing compounds are perhaps the most commonly used

additives for cam oils with other active elements. The sulfur-containing extreme-pressure

additives are believed to form iron sulfide films that prevent wear for high loads and

speeds. Lead soaps have been used in lubricants for many years. They inhibit the wiping

and sliding action in cams and help prevent corrosion of steel in the presence of water.

Other additive compounds contain combinations of these elements and most extreme-

pressure lubricants contain more than one extreme-pressure additive. The selection of a

proper extreme-pressure additive is a complicated process. Factors such as solubility,

volatility, stability, compatibility, load-carrying capacity, and cost must be considered.

Many gear oil companies depend on the use of proprietary or packaged extreme-

pressure additives. As a result, the lubricant manufacturer does not evaluate the additives’

effectiveness. Because of this, any selection of extreme-pressure additives should be sup-

ported by an evaluation program to determine their effectiveness for a given application.

However, a few firms have considerable background in their manufacture and use of

extreme-pressure additives for cam lubrication, and their recommendations are usually

accepted without question by users of gear oils.