Page 297 - Cam Design Handbook

P. 297

THB10 9/19/03 7:28 PM Page 285

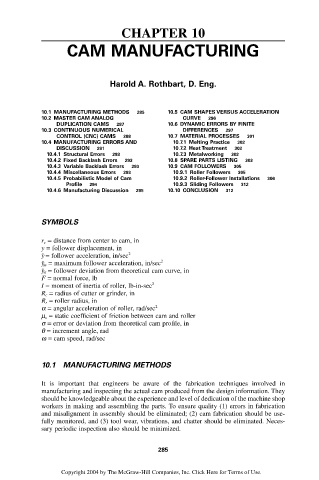

CHAPTER 10

CAM MANUFACTURING

Harold A. Rothbart, D. Eng.

10.1 MANUFACTURING METHODS 285 10.5 CAM SHAPES VERSUS ACCELERATION

10.2 MASTER CAM ANALOG CURVE 296

DUPLICATION CAMS 287 10.6 DYNAMIC ERRORS BY FINITE

10.3 CONTINUOUS NUMERICAL DIFFERENCES 297

CONTROL (CNC) CAMS 288 10.7 MATERIAL PROCESSES 301

10.4 MANUFACTURING ERRORS AND 10.7.1 Melting Practice 302

DISCUSSION 291 10.7.2 Heat Treatment 302

10.4.1 Structural Errors 293 10.7.3 Metalworking 302

10.4.2 Fixed Backlash Errors 293 10.8 SPARE PARTS LISTING 303

10.4.3 Variable Backlash Errors 293 10.9 CAM FOLLOWERS 305

10.4.4 Miscellaneous Errors 293 10.9.1 Roller Followers 305

10.4.5 Probabilistic Model of Cam 10.9.2 Roller-Follower Installations 306

Profile 294 10.9.3 Sliding Followers 312

10.4.6 Manufacturing Discussion 295 10.10 CONCLUSION 312

SYMBOLS

r c = distance from center to cam, in

y = follower displacement, in

y ¨ = follower acceleration, in/sec 2

y ¨ m = maximum follower acceleration, in/sec 2

y ¨ s = follower deviation from theoretical cam curve, in

F = normal force, lb

I = moment of inertia of roller, lb-in-sec 2

R c = radius of cutter or grinder, in

R r = roller radius, in

a = angular acceleration of roller, rad/sec 2

m s = static coefficient of friction between cam and roller

s = error or deviation from theoretical cam profile, in

q = increment angle, rad

w = cam speed, rad/sec

10.1 MANUFACTURING METHODS

It is important that engineers be aware of the fabrication techniques involved in

manufacturing and inspecting the actual cam produced from the design information. They

should be knowledgeable about the experience and level of dedication of the machine shop

workers in making and assembling the parts. To ensure quality (1) errors in fabrication

and misalignment in assembly should be eliminated; (2) cam fabrication should be use-

fully monitored, and (3) tool wear, vibrations, and chatter should be eliminated. Neces-

sary periodic inspection also should be minimized.

285

Copyright 2004 by The McGraw-Hill Companies, Inc. Click Here for Terms of Use.