Page 122 - Carbon Nanotube Fibres and Yarns

P. 122

114 Carbon Nanotube Fibers and Yarns

(A) Amorphous carbon (B)

Less amorphous carbon

10 nm

(C) (D)

Iron impurities

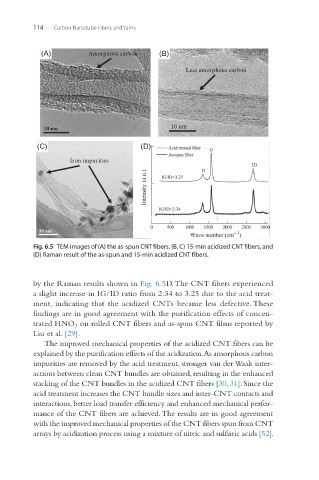

Fig. 6.5 TEM images of (A) the as-spun CNT fibers, (B, C) 15-min acidized CNT fibers, and

(D) Raman result of the as-spun and 15-min acidized CNT fibers.

by the Raman results shown in Fig. 6.5D. The CNT fibers experienced

a slight increase in IG/ID ratio from 2.34 to 3.25 due to the acid treat-

ment, indicating that the acidized CNTs became less defective. These

findings are in good agreement with the purification effects of concen-

trated HNO 3 on rolled CNT fibers and as-spun CNT films reported by

Liu et al. [29].

The improved mechanical properties of the acidized CNT fibers can be

explained by the purification effects of the acidization. As amorphous carbon

impurities are removed by the acid treatment, stronger van der Waals inter-

actions between clean CNT bundles are obtained, resulting in the enhanced

stacking of the CNT bundles in the acidized CNT fibers [30, 31]. Since the

acid treatment increases the CNT bundle sizes and inter-CNT contacts and

interactions, better load transfer efficiency and enhanced mechanical perfor-

mance of the CNT fibers are achieved. The results are in good agreement

with the improved mechanical properties of the CNT fibers spun from CNT

arrays by acidization process using a mixture of nitric and sulfuric acids [52].