Page 126 - Carbon Nanotube Fibres and Yarns

P. 126

118 Carbon Nanotube Fibers and Yarns

Pristine MWCNT

bundles

One MWCNT bundle

GO infiltrated

MWCNT bundles

GO SiO 2

250 nm

GO size < 50nm

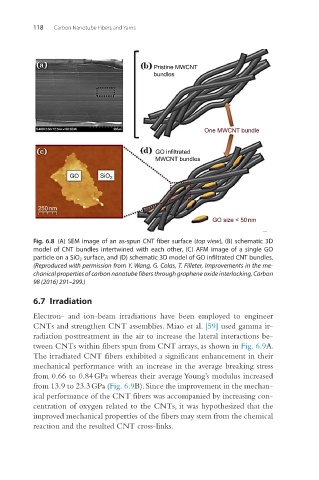

Fig. 6.8 (A) SEM image of an as-spun CNT fiber surface (top view), (B) schematic 3D

model of CNT bundles intertwined with each other, (C) AFM image of a single GO

particle on a SiO 2 surface, and (D) schematic 3D model of GO infiltrated CNT bundles.

(Reproduced with permission from Y. Wang, G. Colas, T. Filleter, Improvements in the me-

chanical properties of carbon nanotube fibers through graphene oxide interlocking, Carbon

98 (2016) 291–299.)

6.7 Irradiation

Electron- and ion-beam irradiations have been employed to engineer

CNTs and strengthen CNT assemblies. Miao et al. [59] used gamma ir-

radiation posttreatment in the air to increase the lateral interactions be-

tween CNTs within fibers spun from CNT arrays, as shown in Fig. 6.9A.

The irradiated CNT fibers exhibited a significant enhancement in their

mechanical performance with an increase in the average breaking stress

from 0.66 to 0.84 GPa whereas their average Young’s modulus increased

from 13.9 to 23.3 GPa (Fig. 6.9B). Since the improvement in the mechan-

ical performance of the CNT fibers was accompanied by increasing con-

centration of oxygen related to the CNTs, it was hypothesized that the

improved mechanical properties of the fibers may stem from the chemical

reaction and the resulted CNT cross-links.