Page 14 - Carbon Nanotubes

P. 14

4 M. ENDO et al.

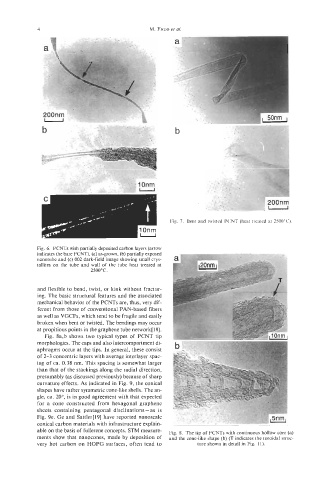

Fig. 7. Bent and twisted PCNT (heat treated at 2500T).

Fig. 6. PCNTs with partially deposited carbon layers (arrow

indicates the bare PCNT), (a) as-grown, (b) partially exposed

nanotube and (c) 002 dark-field image showing small crys-

tallites on the tube and wall of the tube heat treated at

2500°C.

and flexible to bend, twist, or kink without fractur-

ing. The basic structural features and the associated

mechanical behavior of the PCNTs are, thus, very dif-

ferent from those of conventional PAN-based fibers

as well as VGCFs, which tend to be fragile and easily

broken when bent or twisted. The bendings may occur

at propitious points in the graphene tube network[l8].

Fig. 8a,b shows two typical types of PCNT tip

morphologies. The caps and also intercompartment di-

aphragms occur at the tips. In general, these consist

of 2-3 concentric layers with average interlayer spac-

ing of ca. 0.38 nm. This spacing is somewhat larger

than that of the stackings along the radial direction,

presumably (as discussed previously) because of sharp

curvature effects. As indicated in Fig. 9, the conical

shapes have rather symmetric cone-like shells. The an-

gle, ca. 20°, is in good agreement with that expected

for a cone constructed from hexagonal graphene

sheets containing pentagonal disclinations -as is

Fig. 9e. Ge and Sattler[l9] have reported nanoscale

conical carbon materials with infrastructure explain-

able on the basis of fullerene concepts. STM measure- Fig. 8. The tip of PCNTs with continuous hollow core (a)

ments show that nanocones, made by deposition of and the cone-like shape (b) (T indicates the toroidal struc-

very hot carbon on HOPG surfaces, often tend to ture shown in detail in Fig. 11).