Page 553 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 553

516 Carraher’s Polymer Chemistry

Initiators such as benzoyl peroxide are used not only for the initiation of chain-reaction poly-

merization, but also for the curing of polyesters and ethylene–propylene copolymers, and for the

grafting of styrene on elastomeric polymer chains.

Unsaturated polymers such as alkyd resins can be cured or “dried” in the presence of oxygen, a

heavy metal, and an organic acid called a drier. The most common organic acids are linoleic, abi-

etic, naphthenic, octoic, and tall oil fatty acids.

15.8 ANTISTATIC AGENTS—ANTISTATS

Antistatic agents (antistats) dissipate static electrical charges. Insulating materials, including most

organic plastics, fi bers, films, and elastomers, can build up electrical charge. Because these largely

organic materials are insulators, they are not able to dissipate the charge. Such charge buildup is

particularly noticeable in cold, dry climates and lead to dust attraction and sparking.

Antistatic agents can be either internal or external. External antistats are applied to the surface by

wiping, spraying, and so on. These surface treatments act to prevent static charge buildup. Internal

antistats are added during the processing and become an integral part of the bulk composition of the

material. Because surface treatments are often worn away through washing, waxing, and handling,

the external antistats must be replenished. Internal antistats are added to allow the antistats to come

(“bleed”) to the surface over a long time, giving the material long-term protection. Many antistatic

agents are long-chain aliphatic amines and amides, esters of phosphoric acid, poly(ethylene gly-

col) esters (PEGs), and quaternary ammonium salts such as docosyltrimethylammonium chloride

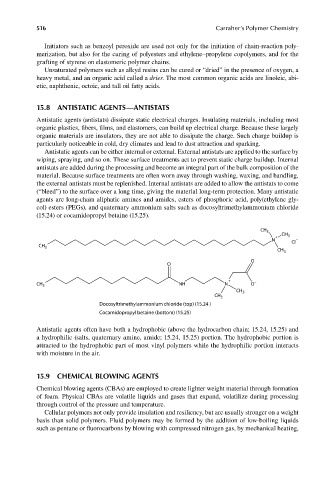

(15.24) or cocamidopropyl betaine (15.25).

CH 3

+ CH 3

N Cl –

CH 3

CH 3

O

O

+ –

NH N O

CH 3

CH 3

CH 3

Docosyltrimethylammonium chloride (top) (15.24 )

Cocamidopropyl betaine (bottom) (15.25)

Antistatic agents often have both a hydrophobic (above the hydrocarbon chain; 15.24, 15.25) and

a hydrophilic (salts, quaternary amine, amide; 15.24, 15.25) portion. The hydrophobic portion is

attracted to the hydrophobic part of most vinyl polymers while the hydrophilic portion interacts

with moisture in the air.

15.9 CHEMICAL BLOWING AGENTS

Chemical blowing agents (CBAs) are employed to create lighter weight material through formation

of foam. Physical CBAs are volatile liquids and gases that expand, volatilize during processing

through control of the pressure and temperature.

Cellular polymers not only provide insulation and resiliency, but are usually stronger on a weight

basis than solid polymers. Fluid polymers may be formed by the addition of low-boiling liquids

such as pentane or fluorocarbons by blowing with compressed nitrogen gas, by mechanical heating,

9/14/2010 3:42:49 PM

K10478.indb 516 9/14/2010 3:42:49 PM

K10478.indb 516