Page 346 - Centrifugal Pumps 2E

P. 346

Chemical Pumps Metallic and Nonmetallic 311

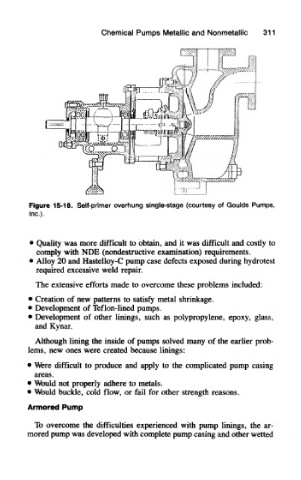

Figure 15-18. Self-primer overhung single-stage (courtesy of Goulds Pumps,

Inc.),

• Quality was more difficult to obtain, and it was difficult and costly to

comply with NDE (nondestructive examination) requirements.

• Alloy 20 and Hastelloy-C pump case defects exposed during hydrotest

required excessive weld repair.

The extensive efforts made to overcome these problems included:

• Creation of new patterns to satisfy metal shrinkage.

• Development of Teflon-lined pumps.

• Development of other linings, such as polypropylene, epoxy, glass,

and Kynar.

Although lining the inside of pumps solved many of the earlier prob-

lems, new ones were created because linings:

• Were difficult to produce and apply to the complicated pump casing

areas.

• Would not properly adhere to metals.

• Would buckle, cold flow, or fail for other strength reasons.

Armored Pump

To overcome the difficulties experienced with pump linings, the ar-

mored pump was developed with complete pump casing and other wetted