Page 349 - Centrifugal Pumps 2E

P. 349

314 Centrifugal Pumps: Design and Application

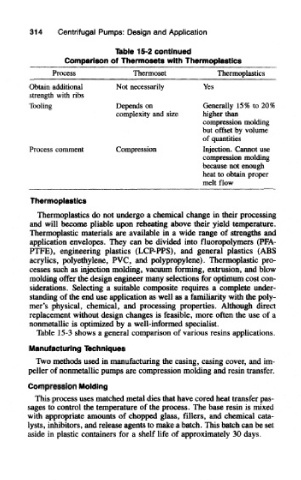

Table 15-2 continued

Comparison of Thermosets with Thermoplastics

Process Thermoset Thermoplastics

Obtain additional Not necessarily Yes

strength with ribs

Tooling Depends on Generally 15% to 20%

complexity and size higher than

compression molding

but offset by volume

of quantities

Process comment Compression Injection. Cannot use

compression molding

because not enough

heat to obtain proper

melt flow

Thermoplastics

Thermoplastics do not undergo a chemical change in their processing

and will become pliable upon reheating above their yield temperature.

Thermoplastic materials are available in a wide range of strengths and

application envelopes. They can be divided into fluoropolymers (PFA-

PTFE), engineering plastics (LCP-PPS), and general plastics (ABS

acrylics, polyethylene, PVC, and polypropylene). Thermoplastic pro-

cesses such as injection molding, vacuum forming, extrusion, and blow

molding offer the design engineer many selections for optimum cost con-

siderations. Selecting a suitable composite requires a complete under

standing of the end use application as well as a familiarity with the poly-

mer's physical, chemical, and processing properties. Although direct

replacement without design changes is feasible, more often the use of a

nonmetallic is optimized by a well-informed specialist.

Table 15-3 shows a general comparison of various resins applications.

Manufacturing Techniques

Two methods used in manufacturing the casing, casing cover, and im-

peller of nonmetallic pumps are compression molding and resin transfer.

Compression Molding

This process uses matched metal dies that have cored heat transfer pas-

sages to control the temperature of the process. The base resin is mixed

with appropriate amounts of chopped glass, fillers, and chemical cata-

lysts, inhibitors, and release agents to make a batch. This batch can be set

aside in plastic containers for a shelf life of approximately 30 days.