Page 105 - Centrifugal Pumps Design and Application

P. 105

86 Centrifugal Pumps: Design and Application

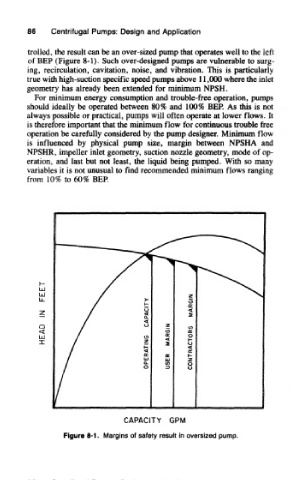

trolled, the result can be an over-sized pump that operates well to the left

of BEP (Figure 8-1). Such over-designed pumps are vulnerable to surg-

ing, recircuiation, cavitation, noise, and vibration. This is particularly

true with high-suction specific speed pumps above 11,000 where the inlet

geometry has already been extended for minimum NPSH.

For minimum energy consumption and trouble-free operation, pumps

should ideally be operated between 80% and 100% BEP. As this is not

always possible or practical, pumps will often operate at lower flows. It

is therefore important that the minimum flow for continuous trouble free

operation be carefully considered by the pump designer. Minimum flow

is influenced by physical pump size, margin between NPSHA and

NPSHR, impeller inlet geometry, suction nozzle geometry, mode of op-

eration, and last but not least, the liquid being pumped. With so many

variables it is not unusual to find recommended minimum flows ranging

from 10% to 60% BEP.

Figure 8-1. Margins of safety result in oversized pump.