Page 106 - Centrifugal Pumps Design and Application

P. 106

NPSH 87

Predicting NPSHR

The other side of the coin necessary for reliable operation is of course

accurate prediction of NPSHR by the pump designer.

In considering NPSHR, it is necessary to understand that a centrifugal

pump is designed as a hydraulic machine to move liquids. Any amount of

entrained air or gas present will cause a deterioration in pump perfor-

mance. Various tests substantiate the claim that a volume of only one per-

cent air or gas will cause a loss of head and efficiency. As liquid travels

from suction nozzle to impeller eye, it will experience pressure losses

caused by friction, acceleration, and shock at blade entry. If the summa-

tion of these losses permits vaporization of the liquid, vapor bubbles will

form in the impeller eye, travel through the impeller, and upon reaching a

high pressure region, collapse. This collapse or implosion of the vapor

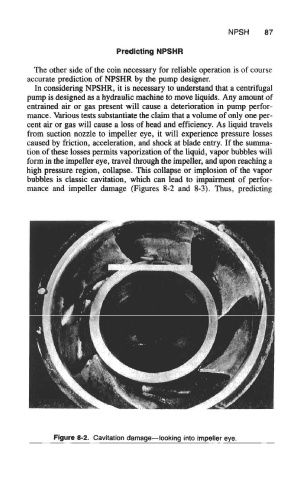

bubbles is classic cavitation, which can lead to impairment of perfor-

mance and impeller damage (Figures 8-2 and 8-3). Thus, predicting

Figure 8-2. Cavitation damage—looking into impeller eye.